What Process Parameters Do Diffusion Bonding Asia Manufacturers Determine?

Diffusion bonding is a modern technique to join solid-state metals under specific temperatures and pressures without melting them. Historically, bonding has played a crucial role as a high-performance technique to join strength and refractory metals. The bonded parts possess high strength, resilience against corrosion, and high favourable temperature properties. As a result, the chemical, medical, energy, and aerospace industries use them on large scale. The diffusion bonding Asia manufacturers use a variety of materials to make high-precision parts. These materials include copper, aluminum, titanium, stainless steel, gold, ceramics, aluminum oxide, magnesium, and nickel, etc. Manufacturers at Stollpche and Vacco apply diffusion bonding through the diffusion of atoms and do not use filler materials. The metal components joined undergo microscopic deformation. However, the joining region is homogenous.

The conventional methods of joining metals become difficult if the physical properties of joining materials are different. The shear strength is possible with diffusion bonding only as it bonds all those materials whose metallurgical and chemical properties are not the same. When atoms on solid metallic surfaces of two metals intersperse under specified hot pressure, the resulting bonding displays the strength. Hence, diffusion bonding becomes favourable in bonding dissimilar materials in which the formation of the brittle phase is unavoidable.

Process Parameters that Influence Diffusion Bonding

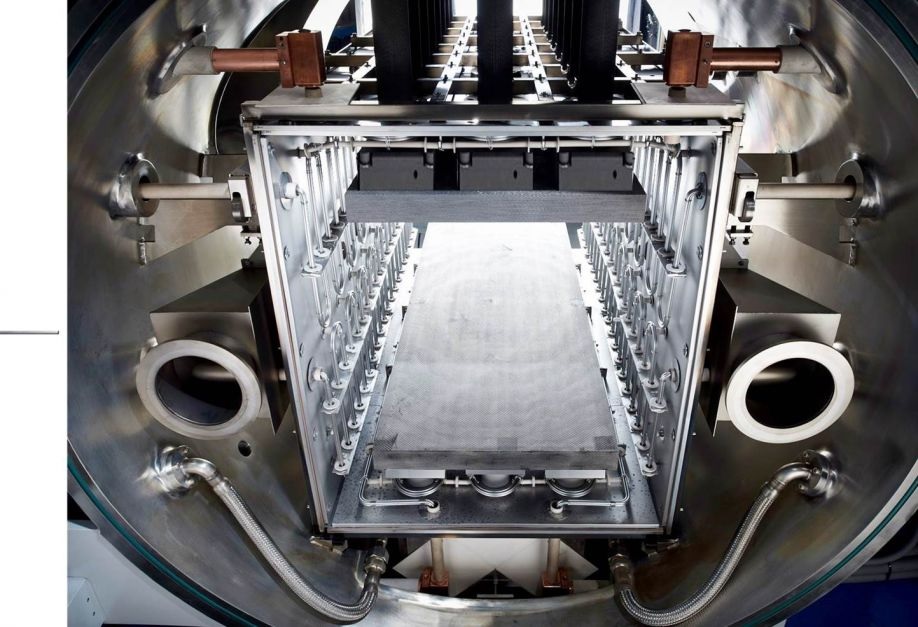

The leading diffusion bonding Asia manufacturers are Stollpche, IET Global Inc., and Vacco . All these suppliers have well-equipped diffusion bonding experts for the successful bonding of the most complex and intricate devices. To meet the bonding criterion, the experts examine the effect of parameters on thickness, strength, and hardness of dissimilar metals.

There are a number of variables that impact successful diffusion bonding. These intrinsic variables are important in assessing the need for dealing with process parameters. The process parameters that may influence diffusion bonding are atmosphere, temperature, pressure, time, and surface preparation.

Surface preparation:

Manufacturers usually apply a thin layer of electroplated or pure Nickel to protect the surface. A clean surface is available at the start for efficient diffusion bonding through polarization of the plating bath.

Atmosphere:

Diffusin bonding Asia manufacturers use a vacuum, an atmosphere of inert, or non-contaminating gas to avoid severe oxidation. This oxidation may result from high bonding temperature. The contamination of oxygen, nitrogen, and hydrogen adversely affects the joining metals’ mechanical properties.

Since diffusion welding accompanies certain deformation of the parts, manufacturers like Stollpche apply three stages of diffusion bonding. The first one relates to the deformation stage . In this stage, the micro protrusions of the rough surfaces come into contact for deformation under high temperature and pressure. The tightly contacted interface provides the condition for atomic diffusion to form several metal bonds.

Temperature

The smooth migration of atoms across the interface and intimate contact requires a certain level of heat. The migration of atoms has an exponential temperature dependence. The diffusion temperature should be around 50 – 80 percent of the melting temperature of most fusible metals from the composition. With the increase in temperature, the yield strength of metal drops. Stollpche attains the necessary plastic deformation in the first stage of diffusion bonding by controlling the temperature. Taking care of some factors, better diffusion bonding is possible. The solidus temperature, the lowest melting constituent in the system, recrystallization temperature, and annealing temperature should not exceed.

Pressure

According to the experts at Vacco, the key component of diffusion bonding is the application of pressure. The primary function of the pressure is to provide intimate contact of the joining surfaces. That is exactly what happens at Stollpche. Their experts apply adequate pressure to create plastic deformation of the surface irregularities to fill void areas.

Time

The time depends upon the relationship existing between the yielding stress and bonding stress at the diffusion bonding temperature. The load per unit area of joint calculates the time. Without sufficient time, it is not possible to have intimate contact. A proper diffusion across the interface takes place only under the appropriate time. If the bonding stress is greater than the yielding stress, the joining components deform plastically causing the intimate contact to complete within no time. However, the greater yielding stress than the bonding stress takes a long time for 100 percent contact area. While joining dissimilar materials, the much longer time tends to alter the chemical composition of the matter. A key point to note is that higher temperature leads to a shorter time for bonding.

The experts at Stollpche obtain a good metallurgical bonding in the third and final stage by keeping an appropriate time. It causes the disappearance of the interface and the hole as the atoms of joining metals to continue to diffuse.

Material Microstructure that Influence Diffusion Bonding

The microstructure of the material itself influences the diffusion bonding. The surface chemistry and metallurgy can impact deformation and quality of joining. The experts at Stollpche give due consideration to this aspect. In the second stage of diffusion bonding, they carry out mutual diffusion and migration of interfacial atoms. To obtain stronger metallurgical bonding, shrinkage, and disappearance of interfacial pores, the experts use recrystallization.

The material parameters such as surface finish, flatness, thickness, and hermetic seal also influence diffusion bonding.

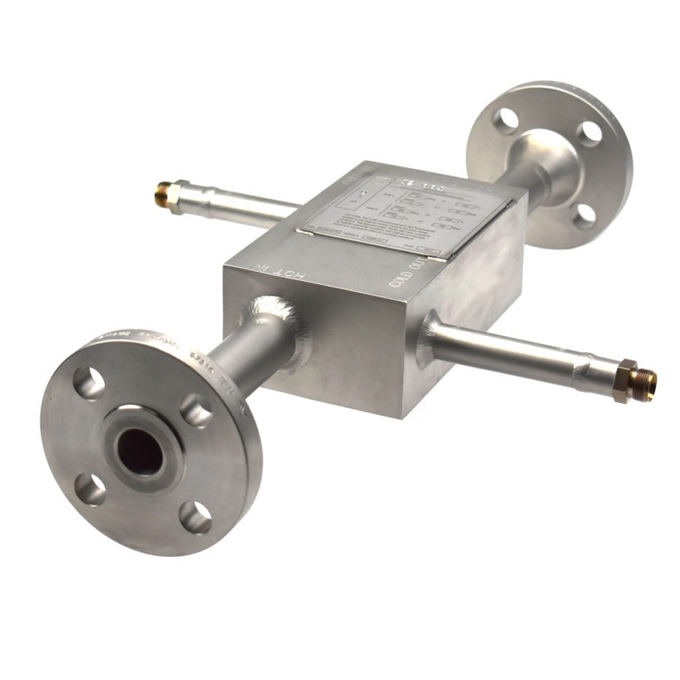

VACCO is an expert in diffusion bonding of titanium and Iron-Nickel alloys, the highly valued metals in various industrial applications. The bonded metals are known for their strength and corrosion-resistant properties.

Summary

Diffusion bonding Asia manufacturers carry out this joining technique in a batch process. Stollpche, for instance, uses three stages for diffusion bonding. The ultimate product is reliable, highly precise, and full of strength. Manufactures including Vacco and IET Global, Inc use diffusion bonding for full intimate contact of metal surfaces. During all this procedure, process parameters including the bonding temperature, atmosphere, pressure, and time play a vital role. Any discrepancy in these parameters leads results in weak joints. In addition, material microstructure including the surface areas, thickness, and hardness, etc. plays a crucial role in diffusion bonding.