Working with the right diffusion bonding isolator is essential for the health and well-being of welding professionals. We've prepared quick tips that involve the safety of the welder:

Give preference to suitable and certified protective equipment, especially those that have direct contact by the professional with hazards such as gases, flames and excessive light;

Define the most suitable equipment for each type of welding application:

Industrial processes involve a wide variety of welding options, such as metals, diffusion bonding isolator electrodes and consumables. Using the right equipment for each type of welding process, you will have greater productivity, more precise finishes and greater safety to perform your activities;

Use certified and verified equipment:

In addition to the direct impact on the quality and results of the processes, opting for top-quality machines, with up-to-date certifications and measurements, enables the preservation of the health and well-being of professionals.

Keep everything clean

It is never too much to remember to pay attention to cleaning the surfaces and benches where the materials will be welded and diffusion bonding isolator.

Follow manufacturers' recommendations

Following the manufacturers' guidelines, whether through tutorials, videos and or manuals, allows you to explore the full potential of your equipment in complete safety and ensuring a longer product life. Furthermore, proper use allows technical assistance and warranty in situations where products need repair;

Qualification and constant training

The qualification of the welding professional with training, qualifications and recycling are essential for maintaining safety and quality.

How to solder electronic components?

Learning to solder correctly is critical for anyone who wants to be a maker. Welding is not an easy skill to master; it requires all the effort and passion typical of a true maker. Certainly, some tips and tricks can help you improve the quality of your solder.

In this tutorial we will cover the necessary materials; diffusion bonding isolator and some techniques that will help you to make a perfect and safe weld.

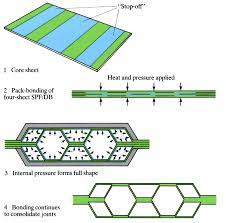

What does bonding mean?

The bonding technique is common a lot in electronics, if you check any circuit board you can see that the components on that board are fixed using this technique. Bonding is the process in which we join two or more electronic components by melting tin into the connection. Tin is a metallic alloy and when it cools it creates a strong electrical connection between the components.

Necessary materials

To carry out the bonding and deboning procedures we need a series of tools other than diffusion bonding isolator. These are as under:

(1) Bonding iron

It is a fundamental tool in the process. They are normally plugged directly into the mains, 110V or 220V, and heat up to temperatures above 400ºC to melt the tin around the electrical connections. For beginner makers it is recommended to use bonding irons with modest powers, from 15 W to 30 W.

These tools also have the functionality of changing their tips; each tip is more suitable for a particular type of solder.

(2) Bonding Station

It is a more improved version of the classic bonding iron. For those who need to carry out large amounts of bonding, a bonding station is a luxury that allows for greater control and flexibility in the task. The main characteristic of this equipment is the possibility of precise adjustment of the temperature of the bonding iron.

The diffusion bonding isolator stations increase the degree of professionalism of your activity and create a safer work environment as many have temperature sensors and alerts.

(3) Bonding iron tips

Most bonding irons have the tip change functionality. There is a wide variety of these bonding iron tips, which vary in size and shape. Each tip is common for one purpose and has an advantage over the other. The most common in maker’s projects are cone-shaped tips and chisel-shaped tips.

Tapered tips are common in precision welding due to their fine tip. As its tip is thin, it is able to heat small areas without affecting surrounding areas. Chisel tips are recommended when bonding wires and large components.

(4) Metal Sponge or Conventional Sponge

The sponge helps keep the diffusion bonding isolator clean and away from oxidation. It is common to see makers using the conventional wet sponge (I have common this type myself in the absence of the metallic sponge). However, wet sponge tends to shorten the life of the bonding iron due to expansion and contraction of the tip metal.

In addition, the wet sponge lowers the temperature of the bonding iron for a while when it is cleaned. The best alternative to using a conventional sponge is the metallic sponge.

(5) Diffusion bonding isolator iron holder

When working with the bonding iron, you will feel the need to keep it in a safe place under safe operating conditions while you work. What I mean is, prevent your bonding iron from coming into contact with flammable materials or even the contact of hot parts with your hands.

Most diffusion bonding isolator already come with this built-in support, the simplest bonding irons have a very fragile and light support (I personally prefer not to use it, only in atypical situations).

(6) Tin as diffusion bonding isolator

As I mentioned above, tin is a conductive metal alloy that is capable of creating an electrical connection between components. Tin may or may not have lead in its composition. When bonding electronic components, it is common to use lead-free tin. Lead-free alloy made of tin and copper, lead-free alloy is 60% tin and 40% lead.

The latter has fallen into disuse due to health concerns and, if you have access to this type of tin, it is necessary to use adequate ventilation for diffusion bonding isolator use and hand hygiene in case of direct contact with the material. Be careful where you buy your tin. Building supply stores usually sell a type of solder that has an acid core.

(7) Magnifier with tweezers–

The tweezers and magnifiers holders have two or more “alligators” that help to hold objects while you use the bonding iron and tin. You will always need a third hand under your control in the bonding activity, especially when you are a beginning maker, so having this item in your lab is very helpful.

(8) Diffusion bonding isolator Solder Suck

The diffusion bonding isolator sucks in the molten solder to separate the soldered components from the circuit board. The solder sucker works best on hole-fixed components but can also be common on SMD components, surface-mounted devices, but is less effective. I would suggest using solder mesh. That said, the solder sucker is one of the cheaper options.