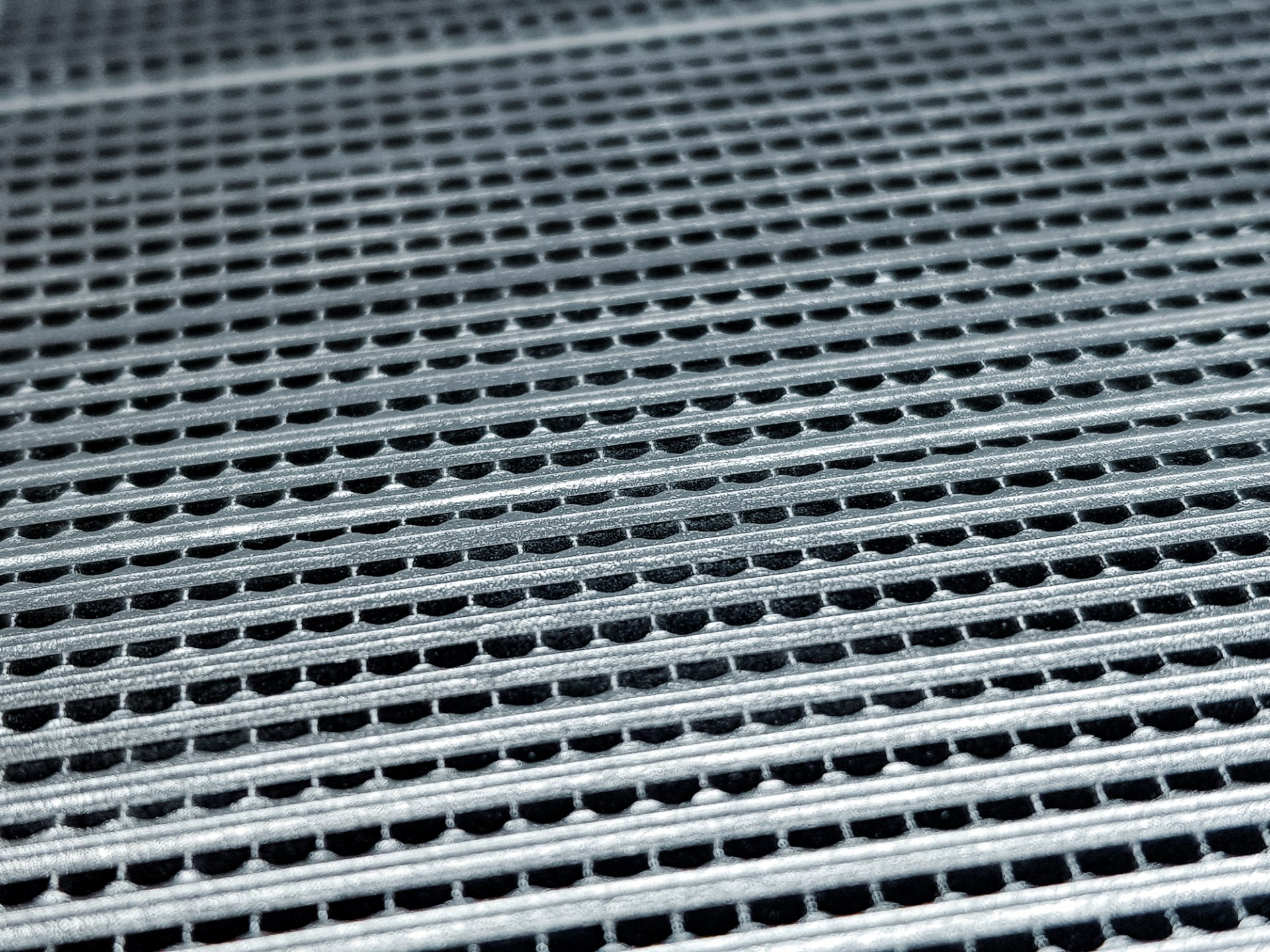

Diffusion bonding supplier is a type of supplier, produced by the process of mutual diffusion that occurs between atoms in the surface layer of the work pieces being welded. The whole process takes place in a protective environment of some inert gas or vacuum using a pressure of 1-25 MPa and a temperature of 50-70% of the melting temperature of the metal of the welded products.

Moreover, diffusion bonding is easy to carry out in automatic and semi-automatic modes, and depending on the force impact, it can be high-intensity and low-intensity.

Advantages: no electrodes and solders; high quality welded joint; relatively low energy costs; the ability to weld work pieces of various thicknesses.

Disadvantages: the need to create a protective environment and conduct a thorough preliminary preparation and cleaning of the surfaces of the products to weld.

How to find diffusion bonding supplier?

The main feature of diffusion bonding supplier is, first of all, obtaining a bond between products at the atomic level. Such work is easy to carry out in automatic or semi-automatic modes. Spatial positions can be very different.

How heat is provided to diffusion?

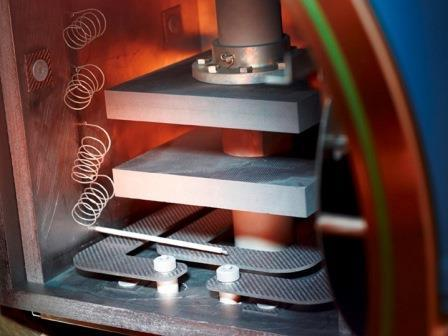

High-quality diffusion bonding services always imply the heating of the treated surface and the use of a protective environment. Heat supplies in a variety of ways. In some cases, the induction, radiation method or heating in a salt solution is common.

Heating by passing current also practice. The required protective environment provides either by the reduced pressure in the chamber, or by the use of a hydrogen medium. After placement in the chamber, the preforms shift so that interatomic cohesion forces begin to act.

The required structure of diffusion bonding supplier the connecting seam forms during the relaxation of the material.

Key features of diffusion bonding

- Compulsory evacuation

- Similarly, increased requirements for the quality of the processed surfaces

- Reduction of energy costs

- Moreover, no need for mechanical preparation of surfaces

- Obtaining excellent seams

- The ability to weld parts and structures with a very wide range of thicknesses

Methods required for this bonding

At enterprises providing diffusion bonding supplier‘s services, this work is easy to perform by various methods:

- electrical contact

- Furthermore, radiation

- induction heating methods

- Similarly, short squeezing

- long pressing

- In addition, local pressing

Enterprise application for bonding

Bonding through interatomic diffusion allows you to join sharply dissimilar materials. It is difficult in any other way to bond steel and bronze, and even more so steel alloys with ceramics. The diffusion process makes it possible to obtain excellent joints of refractory metals without strong heating. It is actively common in industry for:

- receiving sensors

- Moreover, the formation of other electronic devices

- creation of engine cylinder liners

- Similarly, creation of turbine compresses

- development of products designed for extremely high temperatures and pressures

- Furthermore, production of extra hard dies

- Production of complex composites and for some other purposes

It would seem that everyone knows what bonding is and how to find diffusion bonding supplier. But when the need arises to select bonding equipment, gaps in our knowledge suddenly appear. To compensate for them, we publish a thesis reference material.

What is bonding and what types of bonding are?

In industry, construction and repair, various methods of joining structural parts are common. The most widespread are various types of bonding, which fasten not only the same type and dissimilar metals, but also glass, plastic, ceramics. The popularity of the technology is due to the high strength and reliability of the connections.

Definition of the bonding process

Regardless of the type, bonding is popular as the technology of creating permanent joints by heating, deformation, or a combination of both methods. The essence of diffusion bonding supplier is that under the action of an external source of energy, strong bonds form between the materials to join at the interatomic level.

Moreover, after crystallization, during the cooling process, a weld is formed at the joint. Depending on the type of material and working conditions, this is local or general heating and deformation of the abutting surfaces.

Classification of diffusion bonding types

Depending on the criteria, the classification of bonding methods performs according to the type of protection of molten metal from atmospheric oxygen, the method of process control, material, etc. The technological features of bonding are also good to consider. Three main types of bonding are:

Mechanical

Mechanical is carried out by external pressure, under the action of which the surfaces are deformed, which leads to a tight connection and diffusion bonding supplier.

Thermo mechanical diffusion bonding supplier

In thermo mechanical types of bonding, parts are subjected to a combined effect of heat and pressure.

Thermal class of bonding

These bonding methods are performed with the formation of a weld pool of molten metal parts and an electrode or filler material.

What are the bonding methods to join parts?

For bonding we have to find diffusion bonding supplier. The following bonding methods are common to join parts:

Manual: When all manipulations with electrode gas with a temperature of more than 10000⁰C.

Beam and laser bonding: The technology comes on melting the material of parts with a laser light beam or a stream of electrons created by an electron gun.

Both methods are common primarily in the electronics industry for connecting and fixing trace elements. To prevent the beam from scattering, electron beam bonding is carried out in a vacuum chamber.

Laser bonding allows for precise seams. At the same time, the adjacent surfaces practically do not heat up, which excludes deformation of even very thin material. For work in hard-to-reach places, the direction of the beam changes with prisms. Moreover, the process is important to carry out in an inert gas environment.

Thermite diffusion bonding

For bonding of this type, diffusion bonding supplier common a powdery mixture, consisting of aluminum, magnesium, iron oxides. Combustion generates heat which melts the edges of the work pieces. In addition, the molten thermite mixes with the metal of the parts, after crystallization, a compound is formed.

To start the process, the thermite remotely ignites with a pyro cartridge, an electric discharge, and a fuse cord. The combustion temperature of the mixture reaches 2700⁰C. Furthermore, it is sufficient for bonding common types of metals. The thermite method is common to repair large-sized equipment, rails, and splicing wires on power lines.

What is an electro slag bonding?

This type of thermal bonding is common by diffusion bonding supplier to join steel with a thickness of 5 cm to 3 m. The work pieces set vertically; the gap between them closes on both sides with movable water-cooled copper sliders. Similarly, from below, a layer of flux pours onto the pallet, under which an arc ignites.

Conclusion

Furthermore, after the flux melts, the resulting slag becomes electrically conductive. The arc extinguishes, but the current passing through the slag is sufficient to melt new portions of the flux, electrode and edges. As the melt in the weld pool cools down, the sliders gradually move higher.

Finally, in this way, the work pieces are connected in one pass, regardless of their thickness, without cracking.