Conventional Plates

The heat transfer area of exchanger plates offers the most diverse applications. They come with average channels that normally range from 2.2 to 4.0[mm]. Due to the small spacing between the channels, it presents great turbulence and high thermal efficiency.

They have a pair of welded plates. Heat transfer area ensures a more efficient sealing and safety to the fluid flowing in the channel. Medium channels typically range from 2.2-4.0[mm], having the same turbulent effect as conventional plates.

Diverse applications of the heat transfer area

Specific plates are common for instance:

- First, refrigeration

- Second, chemical processes

- Third, specific industrial processes

WIDE-GAP PLATES

Wide-Gap plate heat exchangers provide a wider fluid passage channel than conventional plates, around two to five times larger. Thus, they allow working with fluids containing fibers and coarse particles.

The heat transfer area has contact points between the plates and can have an arrangement of wide channels by conventional channels (Wide x Narrow) and wide channels by wide channels (Wide x Wide).

FREE FLOW PLATES

The free-Flow heat transfer area has a special geometry in the plates that provide a passageway for the fluid without any point of contact between the plates. The passage channel varies according to the model, usually from 7-15[mm].

Free flow plates allow working with dirty fluids, suspended solids, of high viscosity, and with fibrous materials (ex.: juice pulp). Thicker plates, around 0.8-1.2[mm], are common to mechanically compensate for exchanger resistance.

The heat exchanger in the heat transfer area

Have you thought about reducing energy costs in your process? Perhaps knowing a little about heat exchangers is the first step. We present the Pinch methodology common to optimize the use of heat produced in the process itself, reducing electricity costs.

In the heat transfer area, one of the main pieces of equipment involved is heat exchangers. It is essential to understand that there are different types of exchangers. Therefore, we will cover its main features and how you can select the ideal one for your process.

What heat transfer area and what it is for?

Heat exchangers, as the name implies, are equipment designed to exchange or transfer heat from one medium to another. It is done without direct contact between them. In the heat transfer area industry, this medium is a fluid, which can be a liquid or a gas.

An example of our daily exchanger is the air conditioning. It has a coil system that contains a refrigerant gas. In this sense, the coil is responsible for physically separating the air from the environment. The fluid, preventing them from mixing and allowing them to exchange heat is important.

Ambient air in the heat transfer area

In the heat transfer area, there is also a pump that makes the fluid circulate. Thus, when warm ambient air enters the equipment, it loses heat to the cooler fluid in the coil. As a result, ambient air is exhausted at a lower temperature.

Thus, there are several applications for heat exchangers. It is interesting to note that it can be common not only to cool hot streams and heat cold streams, which are direct needs of the process. Also, it is essential for energy use, as in part energy will.

Importance of heat transfer area in Industries

Often in heat transfer area industries from the most diverse sectors, the operating temperature of the processes is of paramount importance. This is because it is responsible for the occurrence or not of chemical reactions, for their yields and speeds.

In this sense, exchangers are thermodynamic equipment. Throughout the entire industrial process, there is always a portion of energy that is wasted. This energy almost always comes in the form of heat. So, exchangers play a fundamental role in energy use.

Types of heat exchangers

However, despite all heat exchangers presenting the same principle, there are several types. And each one of them has different mechanisms. So, understanding its main characteristics is a good start to identifying the ideal one for your process.

In the heat transfer area, we will then discuss the main types of heat exchangers: the plate, shell and tube, and the tubular exchanger. Suppose, for example, that you produce dairy beverages in your industry.

Shell and tube exchanger

The shell and tube exchanger is the most common heat exchanger in different heat transfer areas. These are therefore very versatile. Unlike the plate changer, it is composed, as the name suggests, of two main elements: the hull and a series of tubes placed inside.

Along the various ducts, often hundreds, one of the fluids flows. It is noteworthy that the fluid of interest for which the temperature is to be adjusted. Thus, it is interesting that an analysis is carried out to verify which situation is the most appropriate.

Plate changer in heat transfer area

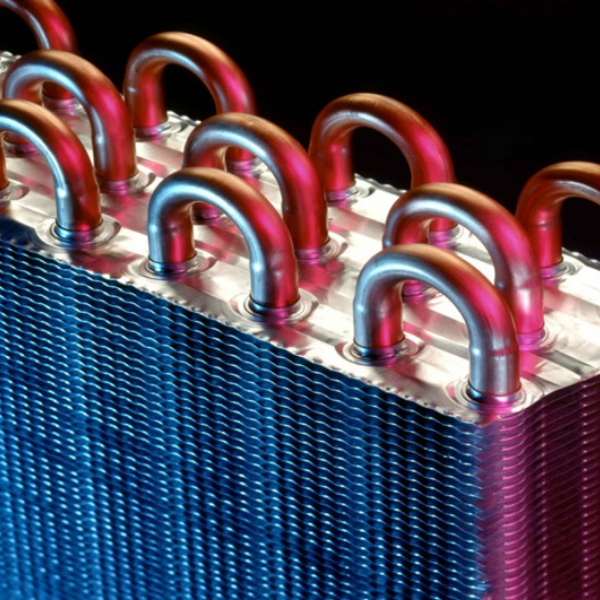

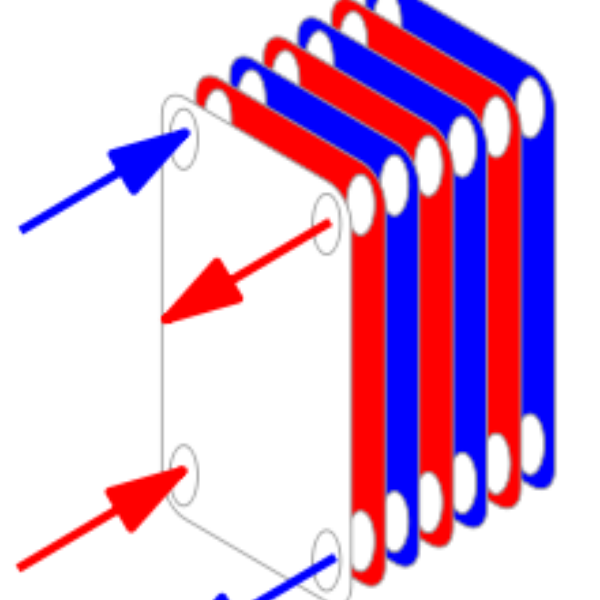

The plate changer consists of a series of parallel plates. These plates are placed one above the other, to allow the formation of fluid channels. Thus, it has two passages, one for the cold fluid and another for the hot one, which circulates in opposite directions (countercurrent).

Heat passes across the heat transfer area on the surface of a plate heat exchanger, separating the hot from the cold medium. As a result, heating and cooling fluids and gases consume very little energy. The theory of heat transfer between a hot medium to a cold medium is simple.

We offer sustainable heat transfer areas solutions for the most diverse industrial and commercial sectors. Today, we are going to show a successful case, installed in a nationally renowned battery factory.

Use of hot water in battery factories

Hot water in a battery factory is easy to use in various processes and activities. In the production sector, hot water is important to wash batteries, wash plastic parts, in the recycling sector when there is in the company and in general cleaning.

Why us?

Our client was looking for innovation and sustainability for their business at the same time. Through our heat transfer areas, we were able to design and offer a heating system that, in addition to not degrading the environment, started to bring much more savings to the company, shortly after installation.