How to Perfect the Diffusion Bonding Technology?

This article will introduce you to perfecting diffusion bonding technology. But, before we tell you how to perfect the diffusion bonding technology, you first need to know about the process in detail. So, let’s dive into the subject.

Introduction

Diffusion bonding technology is a welding process of solid-state where no fusion phase or liquid is involved. The welded joints in diffusion bonding are formed entirely from the solid state. You will notice plastic deformation at the surface of the interface.

You can even join the ceramic materials using this process. The process involves the diffusion of atoms on the joint interface. The entire process of diffusion bonding takes place at an elevated temperature.

The best part about the process is that it does not require any filler materials and the joint process of similar materials is entirely autogenous. You can even use interlayers during the diffusion bonding of dissimilar materials.

The entire process takes place in an immobile environment. The environment plays an extremely important role in the diffusion bonding process. It helps in reducing the oxidation level.

What is the Principle of Diffusion Bonding Technology?

The basic principle of the process revolves around bonding. The principle is the movement of atoms or molecules from a region of higher concentration to the region of lower concentration. High pressure is applied on both the materials that are placed on each other. This helps in setting the process in motion. Moreover, the entire process of diffusion bonding is accelerated by heat. But, the important thing to remember here is that the heat temperature must not be too high. It should only range between 50 to 70% of the metal’s melting temperature.

What are the Advantages of Diffusion Bonding Technology?

Diffusion bonding technology offers a lot of advantages to the users. That’s why this technology is now used everywhere. Let’s take a look at some of the advantages below.

1. Outstanding Joint Performance

One of the main reasons behind the popularity of diffusion bonding is that it offers excellent joint performance to the users. The joints formed through diffusion bonding not only offer strength but a stable quality and good vacuum sealing as well. In addition to this, the properties and microstructure of welded joints for homogenous materials are the same as the base material used. What’s more, the physical and chemical properties do not change after the bonding as well.

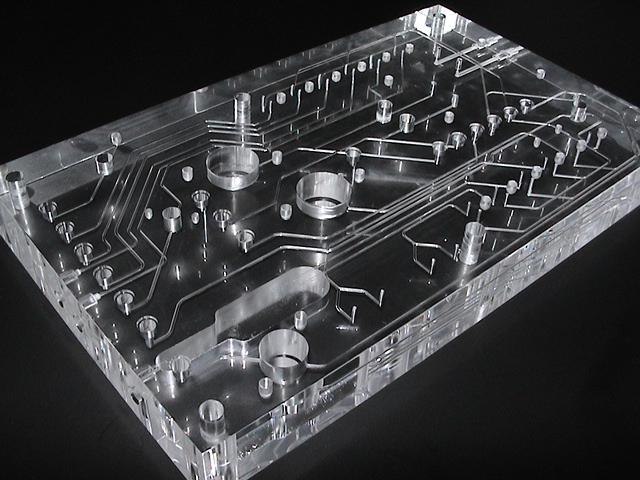

2. Excellent Precision Size

Diffusion bonding technology provides high precision size to the users. That’s because diffusion bonding is a connection technology of solid-state. There is no involvement of solidification and metal melting in the process. What’s more, the pressure that is applied is extremely low as well. As a result, it can very easily block the production of macroscopic deformation. This is what gives the high precision size and geometry of the parts that are bonded.

3. Safe Process

The reason behind the popularity of diffusion bonding technology is that the process is extremely safe. It offers a clean and pollution-free procedure to the users that are completely safe for the environment and the people involved with it. The process does not involve the use of any harmful substances such as radiation or spatter. Furthermore, it is extremely easy to realize automatic control in the process as well.

4. Large Area Connection

You can achieve large area connections with the help of diffusion bonding. But, an important thing to note here is that you need to distribute the pressure uniformly if you want to achieve the large size section.

5. Joins Materials That Are Difficult to Weld

Diffusion bonding can connect materials that are difficult to weld by other means. Whether you want to join homogenous materials that have a high melting point or want to connect heterogeneous materials that are prone to intermetallic compounds, you can do it with the help of diffusion bonding.

What is the Process of Diffusion Bonding Technology?

Generally, the diffusion bonding technology is applied to two or more materials that have almost the same structure as the crystalline. The workpieces are clamped together in the process. But, an important thing to note here is that both the metal surfaces need to face each other. It is extremely important for the successful completion of the project.

Once the materials are successfully clamped, the technicians apply heat and pressure on the workpieces for a lot of time. The surfaces are most commonly heated in a furnace. In some cases, the surfaces are also heated through electrical resistance. You can also use the hydraulic pressure to achieve the pressure that you require. As a result, you get the most accurate measure of the pressure.

Moreover, the surfaces of the bonded material are extremely important as well. You need to machine the metal surfaces for them to be as smooth as possible. Not only this, but the surfaces should also be kept free from chemical impurities and residues. You must also remove the material found between the workpieces. This will ensure the successful completion of the process.

If you are using the metals with strong oxide layers, you must carry out the process in an inert environment or a vacuum. This will ensure that the process is carried out successfully.

Perfecting the Diffusion Bonding Technology

A lot of advancements are now being made in diffusion bonding technology to perfect it. As a result, the limitations faced by diffusion bonding manufacturing are being eliminated now.

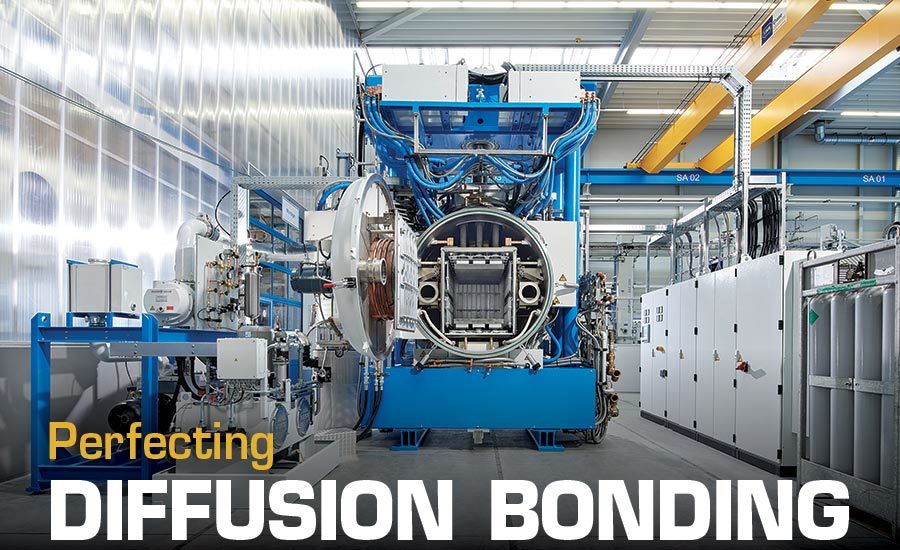

Many sophisticated pieces of equipment are introduced these days that provide pressure control, feedback from pressure transducers, and physical ink test. This allows easy notice of variations in pressure on the surface of the metals that are used in the manufacturing process.

The rapid cooling system and the ability to see variations in pressure help the manufacturers to improve the bond and increase cycle time. In addition to this, the yield per manufacturing process is increased as well.

Final Words

Although the diffusion bonding technology was previously used to join the refractory materials, the technology is now being perfected now. As a result, it is now used in different industries. Contact us now for more information!