What is Diffusion Bonding?

Diffusion bonding is a way of welding solid-state metals. It is especially a part of metalworking that involves joining either similar or different metals using diffusion bonding. To gain the advantage of diffusion bonding is only possible under extremely high temperatures.

In general circumstances, diffusion bonding implements by enforcing high amounts of pressure along with very high temperatures. Many refer to it as the sandwich technique because it resembles it because of all the layers of metal that amalgamate together. It is a very popular technique in the nuclear and aerospace industry because of its high strength characteristics by joining noncompliant metals in a bond.

After reaching the desired amount of temperature, diffusion bonding applies pressure on the metals to co-join them in the form of a layer. Although most hi-tech organizations are using in their procedures, this process dates back to the 1950s. Its earlier use was for making jewelry out of different metals.

Characteristics

When talking about diffusion bonding it makes no use of fusing liquids as well as filler metals. The formed layer does not add weight to the final product. On the other hand, it actually showcases the best qualities of the co-joined metals in a single product.

Usually, diffusion bonding helps in creating a fusion that has the qualities of both the metals especially the strength and resilience. The best part is that the process does not leave the unnecessary amount of residue that can contaminate the bonds formed in the new product.

Nowadays many people are taking advantage of this kind of bonding to formulate new products that have dissimilar qualities. They might even have totally different abilities and variations in their size and physical characteristics.

Unlike other bonding procedures, diffusion bonding can fall towards the pricier side. Despite the fact that it is a costlier option, people know its worth in producing formations that are impossible to weld otherwise. There are many examples already available for the scrutiny of people where they can see the wonder that is diffusion bonding.

Some common bonds achieved through diffusion are between zirconium and beryllium. Both of these materials have properties that vary in their temperature resistance and strength. But the metal achieved after diffusing these dissimilar metals are much stronger physically and can sustain under very high pressures and temperatures. Thus, diffusion bonding is a sure way to of achieving the impossible.

Principle Behind of Diffusion Bonding

Defining diffusion bonding in simple words means that it works on the principle of diffusion. Diffusion is a scientific term that portrays the transfer of atoms and molecules from the state of higher concentration to the state of lower concentration. This process allows even distribution of the particles throughout the bond.

Usually, when performing diffusion an external pressure applies to the materials that you need to bond by placing them over each other. The pressure then gives a push by using heat acceleration that starts the diffusion. It is appropriate to set the temperature ranges that accommodate 50 to 70% of the temperature that the involved metals can bear.

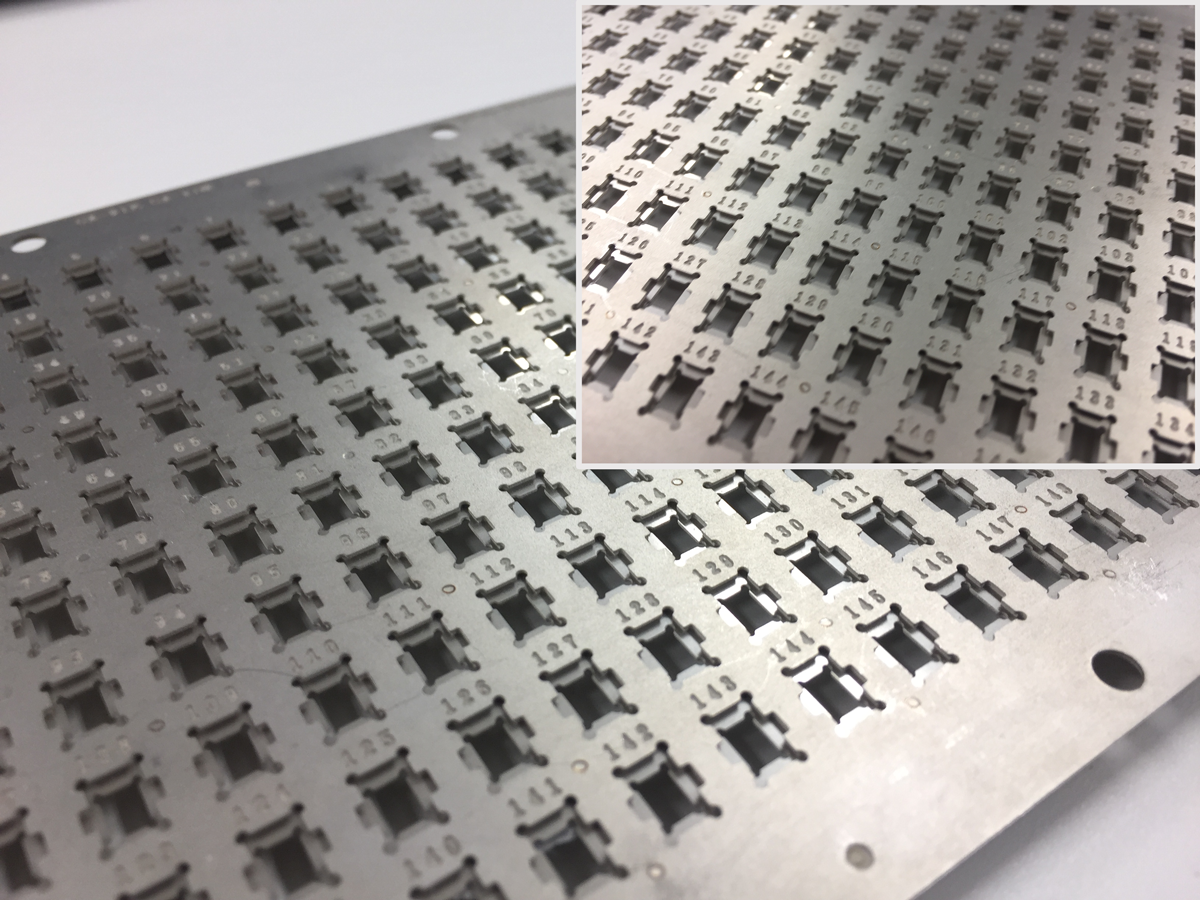

There are many boundaries that need to be set before performing diffusion bonding on the desired metals. For the bond to formulate in the first place, the metals must clamp each other. For this purpose, the surface of each metal must pass through a proper machining procedure to make it as even as possible.

This is done to eliminate any chances of residual formation or impurities left on the surface. Moreover, this bonding takes place through diffusion. It occurs in specially designed spaces that are easily heat-able for the pressure to work its magic. Some even use hydraulic presses due to their very precise results. In some cases, the metals may have solid oxidized layering hence they need different processing. Their bonding takes place in a complete vacuum to achieve the result successfully.

Advantages of Diffusion Bonding

In the modern world where we are coming up with the latest technologies, we come face to face with quite a lot of hindrances, especially in metal bonding. But the advantage of diffusion bonding has successfully provided a way of making metal bonds that are much more strong and resilient. The following are a few advantages of diffusion bonding. These can help in providing a better understanding and its uses for optimal results.

Many manufacturers have a deep concern about losing the mutual qualities of either metal used in obtaining advantage of diffusion bonding. But rest assured that the bonded product shows replicated, if not better, features; be it physical or mechanical. Thus, the material achieved goes through rigorous testing to ensure its quality.

This goes without saying that the product created through diffusion bonding is very crisp and high in quality. The smooth surface achieved after bonding is impermeable. Hence, this is a very intelligent and advantageous way of joining alike and contrasting supplies.

Another added benefit of implementing diffusion for bonding procedures is that it can produce very high precision parts. The latest way of using it involves designing and formatting unusual shapes and configurations.

Thinking in the long run, the cost is pretty much reasonable. Since the complexity of the process is way beyond imagination. The product usually works for a very long time and is quite durable. It can even straighten out any kind of deformation in the mother metals.

The team at stollpche has the latest equipment which helps in providing a unique customer experience. They solely focus on diffusion bonding using vacuum. They are internationally serving as a reliable source for the integration of metals with guaranteed optimized results.

Summary

It is resourceful how diffusion bonding is changing the manufacturing procedures simply by conjoining different and similar metals to get a product that has the qualities of both. Although there are other procedures that are of similar nature, this type of bonding can help produce the impossible. They physically strengthen the bond between the metals for making optimal materials. They are mechanically resilient and physically strong which is a rare combo in naturally available metals.

For More Information on the advantage of diffusion bonding, Contact Us Today!