Everything You Need to Know About a Compact Heat Exchanger

The use of a compact heat exchanger is gaining a lot of popularity these days. But, a lot of people have no idea about what does it do, what are its different types and applications, and how does it work. So, if you are also one of those people and want to know more about the heat exchanger, then keep reading. This guide will tell you everything you need to know.

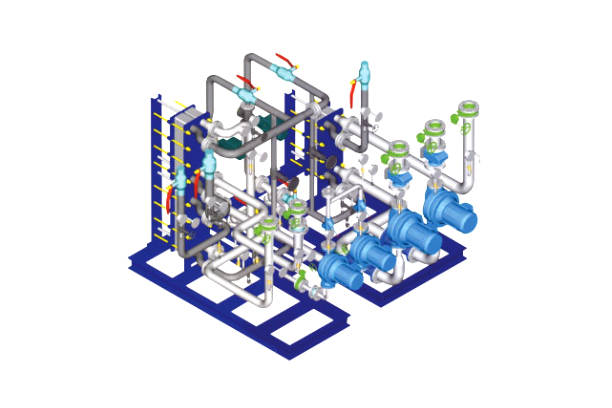

What is a Compact Heat Exchanger?

A compact heat exchanger is known for its high area density. It means that the heat exchanger has an extremely high ratio of heat transfer. It exchanges heat from the transfer surface to the heat exchanger volume.

Thus, a compact heat exchanger defines high warmth move surface-region to volume proportions and high warmth move coefficients. Its surface region thickness is more prominent for gas is discretionarily alluded to as a conservative warmth exchanger. The heat exchanger surface region is expanded by balances to build the surface region per unit volume and there are numerous varieties accessible.

Compact heat exchangers are not a new technology. There is a constant need to create inventive plans to suit market necessities. Such plans are more proficient as far as heat movement. Even though fouling and pressing factor are significant plan contemplations that make conservative heat exchangers not appropriate for all applications.

Some Common Types of a Compact Heat Exchanger

There are many types of compact heat exchangers that the suppliers provide. Some of them are mentioned below for you to check out.

1. Plate and Frame Heat Exchangers

To put it in simple words, the main function of a plate heat exchanger is to design a hot or cold fluid holder without the two devices getting mixed. It might sound exhausting, however, any individual who recollects their thermodynamics realizes that with heat comes energy, and energy is a designing ware. By misusing certain ideas like conduction, entropy, and liquid mechanics, these gadgets can move the warmth starting with one stream then onto the next and you can utilize them as condensers, evaporators, and significantly more. The plate heat exchanger is only one strategy for moving warmth between two liquids and is particularly helpful for heat move between two fluids.

2. Brazed Plate Heat Exchangers

A brazed heat plate exchanger is one of the efficient, compact, and maintenance-free options for heating available out there. Moreover, you can even use it for evaporation, cooling, and condensing multiple applications. It is different from other heat exchangers because it has no header, sealing gasket, or tie bar. It brazes the plates at a temperature of 1100 degrees centigrade. The suppliers use a sheet of brazing material during the assembly process. This sheet is generally made of copper but sometimes the manufacturers use nickel as well. They place the sheets between the plates and press them for some hours. As a result, the sheets are baked.

3. Polymer Heat Exchanger

Polymer heat exchangers are widely used by suppliers nowadays. They are made of thermoplastics such as PVDF, PTFE, PP, PE, PC, PPS, etc. It is capable of handling any free-flowing powder and crystalline solids. This is what makes it a perfect choice for heating and cooling applications. What’s more, its maintenance and operating costs are extremely low as well. This is why it is one of the most popular types of compact heat exchangers.

Advantages of a Compact Heat Exchanger

Working with a compact heat exchanger offers many benefits to the manufacturers and the users. Let's check out some of them below.

1. Close Approach Temperature

The very highlights that give the compact heat exchanger its high productivity additionally make it conceivable to arrive at close methodology a temperature which is especially significant in heat recuperation and recovery applications. Approach temperatures of 1ºF are conceivable.

2. High Efficiency

The squeezed plate examples and tight holes consider extremely high disturbance at moderately low liquid speed. Joined with counter directional stream brings about exceptionally high warmth move coefficients.

Minimized size and high proficiency require less warmth move region bringing about a lot more modest warmth exchanger than would be needed for the indistinguishable adequacy of other warmth exchanger types. Ordinarily, a compact heat exchanger requires 20-40% less space than needed by a shell and cylinder heat exchanger.

3. Easy to Clean and Remove

You just eliminate the tie bolts and slide back the versatile casing. The plate pack would then be able to investigate, pressure cleaned, or eliminate for restoration if essential.

4. Multiple Duties in a Single Unit

You can build a compact heat exchanger in sections. As a result, you get straightforward divider plates or more convoluted divider outlines with extra associations. This makes it conceivable to warm, recover, and cool a liquid in one warmth exchanger or warmth or cool various liquids with a similar cooling or warming source.

5. Low Cost

High warmth move coefficients mean less warmth move region and more modest warmth exchangers, and once in a while significantly fewer warmth exchangers. This and fewer space prerequisites decreased stream rates, and more modest siphons mean.

Disadvantages of a Compact Heat Exchanger

While a compact heat exchanger offers many advantages, there are some disadvantages to it as well.

- Higher initial cost

- Difficult to find leakage

- Limited operating temperature

- Joints may deteriorate over time

Applications

Different industries use different types of compact heat exchangers. Let’s take a look at some of them below.

- Food and Drink Industry

- Chemical and Petrochemicals

- Oil and Gas Processing

- Paper and Board

- Prime Movers

- Textiles and Fabric Care

- Mechanical Vapor Recompression

- District Heating/Cooling

- Refrigeration

- Air Compressors

- Cryogenics

Final Words

We hope this guide answers all your questions about what a compact heat exchanger is, what are its types, advantages, disadvantages, and applications. However, if you still have any questions, feel free to reach out to us.