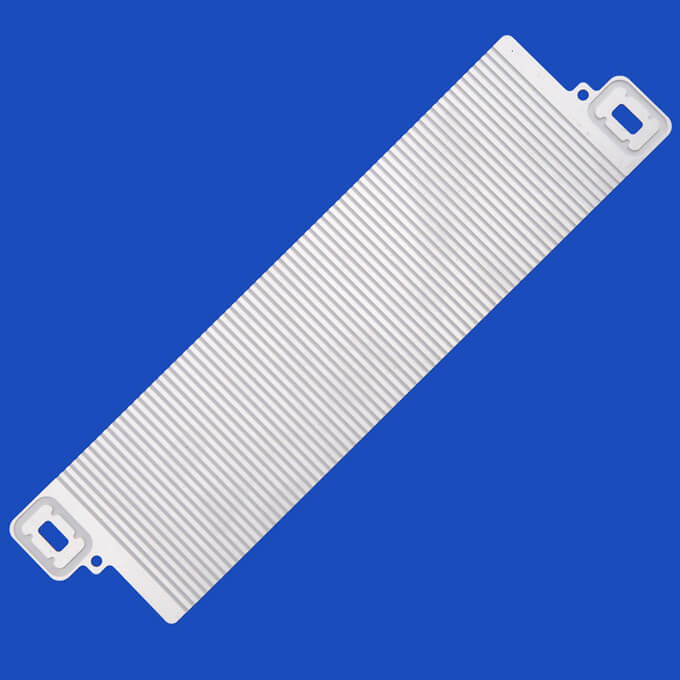

The operating instructions indicate how often a specific custom micro channel perforated flow plate must be cleaned. These times are best adhered to, although cleaning more frequently sometimes recommend. However, on average, it carries out once every 3–4 years, provided that a non-rigid coolant and a mechanical washing filter use.

Liquids and means for flushing the flow plate

The content of the article:

- Background of the problem

- How to choose a liquid for flushing the flow plate

- In what form are the reagents for sale

- Rules for Disposal of Flushing Products

- Popular means for flushing the flow plate

Moreover, means and liquids for flushing custom micro channel perforated flow plate perform a restorative function, helping to restore the original performance and heat transfer characteristics of the pipeline, boiler and batteries.

Background of the problem

The reason for the decrease in the efficiency of heating equipment is banal and simple: the water circulating in pipes and radiators contains impurities. Therefore, various dense deposits settle on the walls of hollow products, elements of boiler equipment after a long service life, reducing the thermal conductivity of the system several times. As a result, the temperature in the living quarters drops.

In order for the heating to work as it should in winter and to be warm and comfortable in the heated house. However, you should take care of cleaning the systems before the start of the heating season. These measures will also help save money intended for heating.

The most effective method for eliminating scale in pipes is treatment with special reagents.

How to choose a liquid for custom micro channel perforated flow plate?

When choosing a flushing product, professionals urge to be guided by a number of criteria.

- The flow plate flushing fluid may contain either acidic or alkaline components. The former activates as quickly as possible, but interaction with them requires extreme caution. Moreover, there is a danger of damaging the washed items and causing damage to health.

- The latter are safer, but not as efficient in operation. To achieve a positive result, you will have to spend a lot of time.

Choose a product with an anti-corrosion effect

If the flushing liquid is not provided with this function. It will be necessary to additionally treat the system with a special custom micro channel perforated flow plate with inhibitors and passivators that prevent the corrosion process from starting.

Before using, and better before purchasing the selected product, you should make sure that it is suitable for the material from which the pipes and other elements of the flow plate are made. Moreover, if this neglect, you can damage the equipment and spend a lot of money on its replacement.

In what form are the reagents for sale?

Flushing the heating with chemicals will help keep the system in order. Experts say that this kind of prevention should be organized annually. However, chemical reagents in custom micro channel perforated flow plate for flushing heating equipment are available in three types:

- Concentrate - before use, it dilutes with water in proportions according to the manufacturer's instructions;

- Powder - in the same way to be diluted with water;

- Finished composition.

Rules for Disposal of Flushing Products

By adding special components to the preparations, working out after washing allows to discharge into the general sewer. This fluid is biodegradable. Moreover, if the reagent does not contain biodegradable additives, then a neutralizer must be added to it.

Popular means for flushing the custom micro channel perforated flow plate

To prevent clogging of pipes and batteries, experts in the field recommend the use of safe flushing chemistry. However, today, the domestic market sells such solutions and concentrates that are able to flush flow plates of any configuration.

In order for the flow plate to work efficiently and for a long time, it is necessary to regularly flush it. The procedure consists in cleaning parts and assemblies from accumulated contaminants. It carries out as part of the maintenance of equipment.

The technical condition of the custom micro channel perforated flow plate directly affects the performance of the gas boiler. A flow plate is a pipe structure in which water or other coolant circulates. It locates slightly above the firebox. Moreover, this is due to the possibility of rapid heating of the coolant as a result of gas combustion.

Water is the most common coolant

Often, metal salts, lime and other elements dissolve in it. Scale forms at temperatures above 60–80 degrees. However, salts decompose into an insoluble precipitate and carbon dioxide. Also, scale can occur with electrostatic adhesion.

The thickness of the plaque grows over time, the movement of water becomes more difficult. Moreover, this leads to failures in the operation of the custom micro channel perforated flow plate.

Signs indicating the need to clean the heat exchanger:

- The boiler burner is on all the time;

- A characteristic hum appears in the operation of the pump, indicating an overload;

- Heating takes longer than before;

- Gas consumption is increasing;

- The water pressure in the faucet drops.

Methods for cleaning custom micro channel perforated flow plate

The method bases on the physicochemical reactions that occur in a liquid when an electric discharge passes through it. The deposits break up and wash away with water. The advantage of the method is accessibility. The disadvantage is the uneven cleaning and its low speed.

Hydrodynamic: removing of scale

The technique consists in supplying water under high pressure to the boiler and removing scale to the outside. Moreover, this method allows you to release pipes from contamination faster than the previous one.

Mechanical: disassembly of the equipment

When cleaning, manual tools and automated units use. The technique involves partial or complete disassembly of the custom micro channel perforated flow plate.

A process with high efficiency and minimal time costs

Reagents use for cleaning. They dilute with water and run into the system. Circulating through the pipes, the chemicals dissolve the deposits and bring them out. The method characterizes by high efficiency and minimal time costs.

Removing the heat exchanger for cleaning

To clean the flow plate, they usually need to remove from the boiler system. Moreover, the process does not require special equipment and involves:

- Removing the front cover;

- Draining water and relieving pressure;

- Removing the combustion chamber cover (in some models it is hidden behind rubber seals, noise and heat insulating materials);

- Disabling water flow and temperature sensors on the custom micro channel perforated flow platenozzles;

- Removal of fasteners and removal of the heat exchanger.