The stability of operation and durability of the custom micro channel porous flow plate directly depend on the regular maintenance and cleaning of elastic gaskets, plates, other components and parts from contamination. For this purpose, special means are common for flushing flow plates. What they are, consider below.

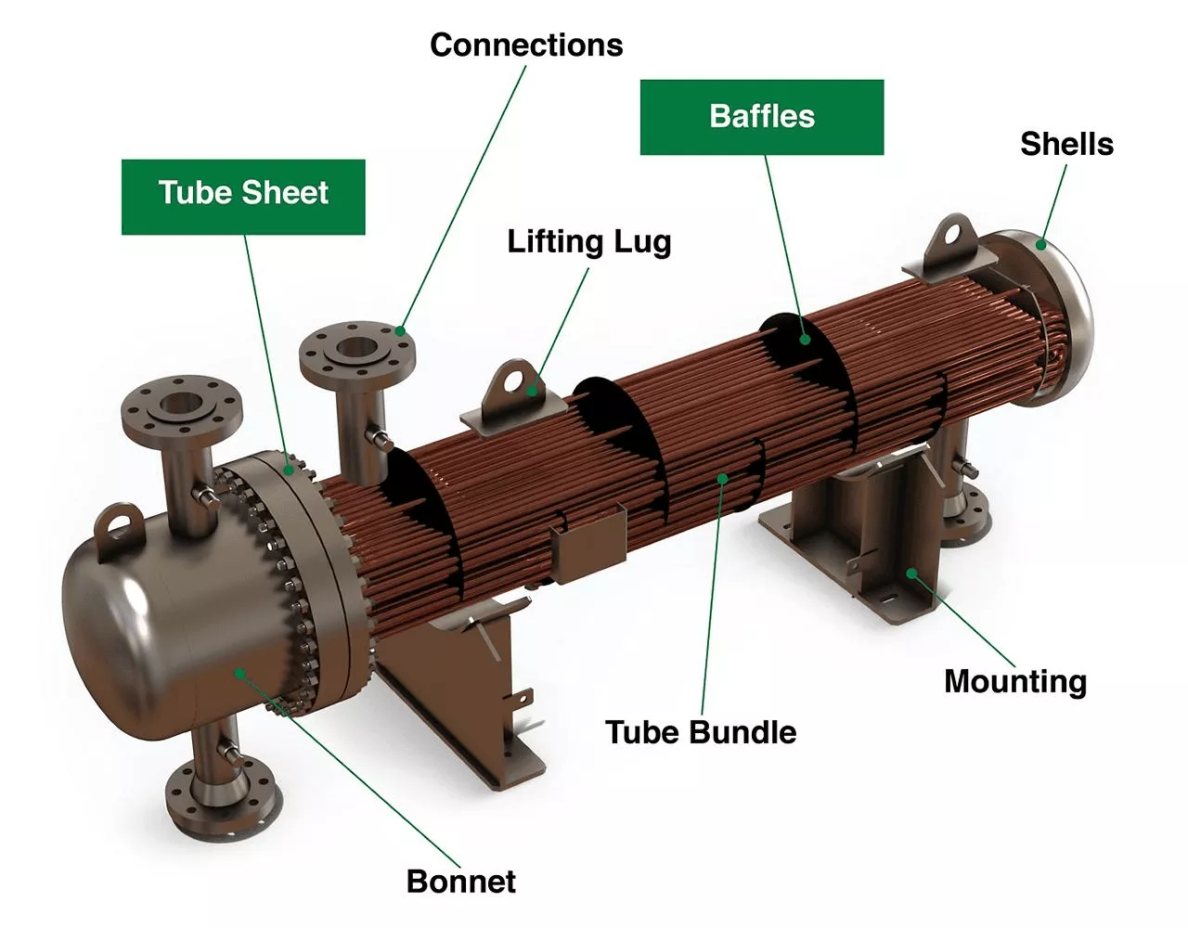

Classification of plate flow plates according to design

According to the principle of operation, plate flow plates are divided into three categories.

- One way designs. The coolant circulates in the same direction over the entire area of the system. However, the basis of the principle of operation of the equipment is the counter flow of liquids.

- Multi-way units. custom micro channel porous flow plateis common in cases where the difference between the temperatures of liquids is not too high. Moreover, the coolant and the heated medium move in different directions.

- Dual equipment. Considered the most efficient. Such flow plates consist of two independent circuits located on both sides of the products. In addition, by adjusting the power of the sections properly, you will quickly achieve the desired results.

Manufacturers produce collapsible and brazed plate flow plates

- Products of the first group are more popular. Such units are common in industry and hot water systems. Moreover, collapsible models are easy to maintain and repair. However, the power of the equipment is adjustable.

- In custom micro channel porous flow plate, the plates rigidly interconnect and place in a non-separable housing.

In addition, rubber gaskets are missing. Such models are most often common for heating or cooling water in private homes.

Selection of plate flow plates according to technical characteristics

When choosing a flow plate, pay attention to:

- The desired temperature for heating the liquid;

- Maximum coolant temperature;

- Pressure;

- Coolant consumption;

- The required flow rate of the heated fluid.

In addition, manufacturers produce equipment with different technical characteristics. However, specialized software and specialist services simplify the search task. Typically, units configure to produce a 70°C liquid outlet.

Applications of custom micro channel porous flow plate

Reliable and efficient plate flow plates are common in various fields.

- Oil industry. The equipment is common to cool processed energy resources.

- Heating and hot water systems. Installations heat the liquids supplied to consumers.

- Mechanical engineering and metallurgy. Moreover, the equipment is common for cooling machine tools and equipment.

- Food industry. Flow plates, for example, are part of pasteurization plants.

- The devices cool various equipment and heat sea water on ships.

This is only a small part of the scope of flow plates.

Types of pollution: during process

The liquid coolant has in its composition various dissolved elements, which, when heated, decompose, forming an insoluble precipitate - scale. However, in most cases, pollution form by:

- Organic and fatty deposits;

- Calcium carbonate;

- Iron oxide;

- Salt;

- Lime stone.

Plaque gradually builds up on the inner walls of the heating equipment. If you do not carry out regular cleaning, the thickness of the sediment increases. Moreover, this impedes the circulation of the working medium, reduces the efficiency of the apparatus and prevents its normal operation.

Washing methods of custom micro channel porous flow plate

Collapsible plate flow plates are washed by chemical and mechanical methods. The first option, as a rule, does not require disassembly of the equipment, due to which it is the most popular. However, mechanical cleaning needs when heavy contamination detects. Moreover, the technique involves the dismantling of the system and involves significant labor costs.

Choice of cleaning chemicals

Moreover, when choosing a chemical reagent for cleaning a flow plate, the main rule is:

The components of the chemical reagent must be aggressive towards scale, but neutral towards the exchanger plates, elastic elements and other parts of the system. However, this is the only way to effectively eliminate contamination without harming the mechanisms of the unit.

Criteria for choosing a flushing custom micro channel porous flow plate:

- Thickness and amount of plaque on the walls inside the equipment;

- Material for the production of gaskets and plates;

- Chemical composition of pollution.

In addition, to reduce the risk of damage to the internal parts of the system, it is recommended to analyze the resulting sediment, and based on the data obtained, choose the most effective, but safe means.

Types of cleaning solutions for flow plates

Three types of cleaning agents are produced for cleaning flow plates:

- Powders;

- Concentrated liquids;

- Ready solutions.

The first two types are called reagents. They require preparation before use on custom micro channel porous flow plate. Moreover, means are diluted with water in the proportion indicated by the manufacturer.

The composition of the modern detergent

In addition, modern reagents and ready-made solutions are characterized by a wide range of chemical active substances in the composition. Moreover, Concentrates may include:

- Organic acids;

- Acid corrosion inhibitors (prevent the destruction of system elements);

- Chemical reagents;

- Defoamers;

- Components that form a protective film on internal surfaces.

The detergent should loosen the carbonate contamination, transfer it to a liquid state for removal from the custom micro channel porous flow plate. Moreover, many manufacturers offer liquid color change agents for process control. This eliminates the need to use test strips to measure the pH level at different cleaning stages.

In addition, an alternative to chemicals is a mixture based on caustic soda and sodium carbonate. It is less harmful to human health, but not all pollution can be eliminated. However, it can be common to remove fats, oils, biological substances.

Flushing the gas boiler at home

The gas boiler can be cleaned at home. The need to do this arises with such signs:

- Characteristic hum of the circulation pump, which indicates an overload of the system;

- Burner working without interruption;

- Long heating of the radiator;

- Weak water pressure (double-circuit boilers);

- Increase in gas consumption.

The following preparations are applicable for home cleaning:

- Lemon acid. It effectively removes scale if the solution is heated to 60 degrees. Suitable for cleaning systems made of brass, copper, stainless steel.

- Sulfamic and adipic acids: Sufficient for regular cleaning with light soiling. Eliminate metal oxides. Moreover, suitable for equipment made from different metals.

- Hydrochloric acid. Removes heavy residue. Common for copper and steel flow plates. However, it can be dangerous for products made from other metals.

- Orthophosphoric acid: Removes scale and dirt. An additional advantage is the formation of a protective film.

- Water soluble gels. However, they are a little aggressive in relation to the elements of equipment and remove dirt well.

When cleaning boilers and custom micro channel porous flow plate, it is important to take precautions - wear goggles, gloves, respirators.

Conclusion

However, to clean heating equipment, it is better to use industrial concentrates, rather than self-prepared compounds. It is worth choosing mixtures with corrosion inhibitors. Moreover, this gives additional protection to metal elements.