What is a plate heat exchanger?

A custom micro channel porous plate is a device used to exchange heat between two or more cooling water circuits. It is standard equipment in marine systems, power plants and chemical processes.

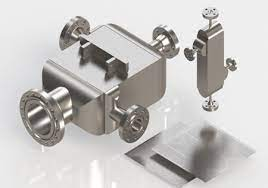

The purpose of any plate heat exchanger is to move energy from one circuit to another by means of the plates. It consists of a series of plates, which are made of metal which has good thermal conductivity. The plates stack together, with a gasket between each layer. they are then held in place by a frame.

Operation of the custom micro channel porous plate

The total amount of liquid passing through the exchanger divides equally according to the number of plates in the exchanger. Each second plate generates a circulation channel through which one of these portions of liquid flows.

Thanks to this mechanism and the corrugation of the plates, the circulation speed increases considerably, creating a turbulent flow that reduces the risk of fouling and optimizes the heat exchange, so that the fluid reaches 100% of its temperature at the end of the path of each plate.

Three important aspects to consider regarding the custom micro channel porous plate are:

- Ultra-thin plates with a high heat transfer coefficient are more efficient.

- Today's heat exchangers require very little space to install, compare to older shell and tube heat exchangers.

- In addition, they are easy to maintain because they are quick and easy to disassemble and clean in case of encrustations.

Custom micro channel plate with heat exchanger gasket

However, it is the unique ripple pattern imprinted on each heat exchanger that is capable of producing a higher heat transfer rate.

Another advantage of the custom micro channel porous plate is that since almost all the material use to exchange heat, its effective heat transfer capacity is very high on a small surface. Furthermore, being five times smaller, it has the same heat capacity as a shell and tube heat exchanger.

Plate heat exchanger

The superior design of the plate heat exchanger line ensures maximum long-term customer satisfaction:

- The high quality gaskets allow a watertight seal and a quick and easy maintenance.

- Double seals minimize the possibility of the two fluids mixing.

- Leak detection which, in the event of a gasket break, diverts the leak outwards.

- Zinc bath which guarantees a long life to the equipment.

- Easier assembly and disassembly due to the fact that all parts thread and can adjust from the fixed front custom micro channel porous plate.

- Easily expandable as needed.

Replacing the boiler exchanger is one of the most common component replacement operations during the life cycle of the boiler. In fact, the plate heat exchanger is often subject to obstructions and clogging mainly due to the accumulation of limestone. By following this step by step guide you will know how to change the boiler plate heat exchanger.

How to replace the boiler heat exchanger?

The secondary exchanger is responsible for the contactless heat exchange between the heating circuit and the sanitary one, the water of which flows between the custom micro channel porous plate with a multidirectional flow to improve heat exchange.

Once the boiling water entering the exchanger has transferred heat to the cold incoming water, hot water comes out and enters the sanitary circuit. This water will use to shower, brush our teeth or simply wash the dishes.

How the boiler exchanger works?

Unfortunately, there is no exact answer to the question when to replace the boiler exchanger. The exchanger has a limited life whose duration depends on the frequency of use of the boiler, on the set temperature and above all on the quantity of limestone present in the water which varies from area to area.

Over time the limestone accumulates between the custom micro channel porous plate of the exchanger until it reaches a complete obstruction of the ducts through which the water passes. This is what a boiler exchanger looks like to change.

Heat exchanger blocked by limescale

The result is that we often find ourselves taking a cold shower or with a very small jet of hot water. In extreme cases, the clogged exchanger can puncture. Over time, the limestone corrodes the plates of the exchanger to create one or more holes. If you have high pressure in the boiler. It could be due to the custom micro channel porous plate hot water exchanger.

The high pressure in the boiler causes the water to drain from the safety valve which attempts to lower the pressure and bring it back below 2 Bar. In these cases, a simple cleaning is no longer sufficient. If you want to change the boiler sanitary exchanger you can buy it on our e-commerce with fast delivery.

How to replace the boiler exchanger?

The secondary exchanger locates under the combustion chamber. It can mount horizontally or vertically. First, we disconnect the boiler from the power supply, shut off the incoming gas and water. Then put on safety devices such as a mask, protective goggles and gloves.

Wear personal protective equipment, turn off the gas and unplug the electrical plug. Then we drain the water from the boiler and cover the electronics with a cloth to prevent any residual droplets from damaging the custom micro channel porous plate.

At this point we access the area under the combustion chamber, identifying the housing where the exchanger locates. There are three main types of exchangers and they differ in the way they fix to the boiler:

Domestic hot water exchanger with threaded and plug-in fittings

This exchanger usually connects directly to both pipes and other components such as the three-way valve. Here the disassembly process can be more complicated as it may be necessary to first disassemble the connected components in order to remove the exchanger from its housing.

Exchanger with threaded and O-RING fittings

To reduce the build-up of limescale in the boiler exchanger, we recommend installing a polyphosphate dispenser or other anti-limescale products. In this way you will be able to extend the life cycle of your custom micro channel porous plate even in areas where the water has a high amount of limestone.