For heat exchanger, test rings and seals are important

To restore the seal of a pipe that has a leak in correspondence with the fixing on the titanium micro channel perforated plate, if the seal carries out by expanding the pipe, restore the seal by expanding the pipe, sometimes after expand a leaking pipe.

It is necessary to expand also adjacent pipes, if the seal is by welding between pipe and plate, it is necessary to restore the weld.

Operations must be carried out with suitable equipment

In case of disassembly of the heat exchanger, at the time of reassembly, it is advisable to replace the old gaskets with new ones; the gaskets during assembly crush and deform and during use they tend to become brittle.

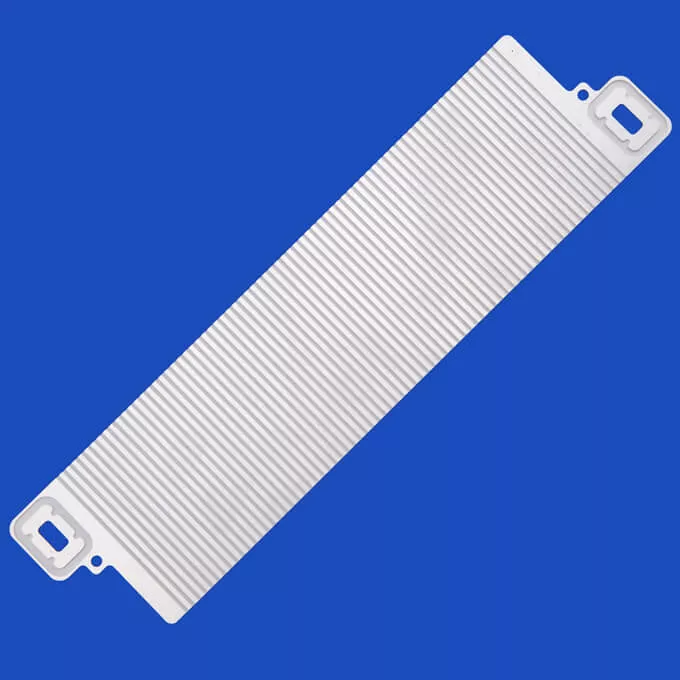

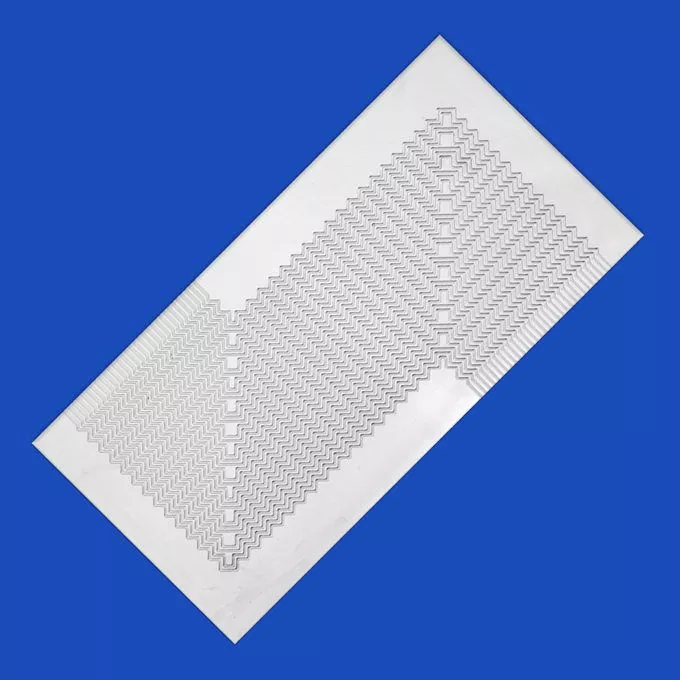

Maintenance components of the titanium micro channel perforated plate

The maintenance of the heat exchanger is therefore a fundamental component to guarantee its correct functioning. Correct operation of a U shell and tube heat exchanger, according to the specifications for which it designs, directly affects productivity and therefore the production cost of the finished product.

Unfortunately, all the exchangers, based on the nature of the fluids that pass through them, are prone to get dirty with a consequent decline in performance in terms of heat transmission. To reduce the impact of the deterioration of the performance on the cost of the product.

It is necessary to monitor the exchanger and arrange for an adequate scheduled maintenance of the U shell and tube heat exchanger.

Pipe maintenance of the heat exchanger

Maintenance of the titanium micro channel perforated plate consists of keeping the pipes clean. Moreover, the internal and external cleaning of the pipes can carry out, if the materials allow it, with descaling solutions; furthermore, a mechanical cleaning can carry out on the outside of the pipes in the event of limestone deposits, after extract the tube bundle from the shell.

The tube bundle can be easily extracted the after removing head

A series of spare gaskets must always be available, to replace after maintenance interventions. The insulating coating is preferable to carry out after installation to avoid damage during transport and installation.

Main types of encrustations in titanium micro channel perforated plate

Here is a list of the main types of encrustations that can encounter:

- Particulate matter;

- Corrosion;

- Biological material;

- Crystallization;

- Chemical reaction;

Moreover, it is not certain that the fouling cause by a single mechanism, in several cases multiple conditions can occur at the same time; the fouling tends to increase over time.

In fact, the “Tabular Exchanger Manufacturers Association” recommends, in the design field, to consider an admissible encrustation in order to be able to use the exchanger even if slightly dirty to clean it up as soon as possible.

Ordinary and scheduled maintenance micro channel perforated plate

A U shell and titanium micro channel perforated plate maintenance allows to extend the life of the exchangers and to continue to have from them the performances for which they designed.

Moreover, a well-performed routine maintenance also allows you to save in the long term, as the cost is certainly lower than that to be incurred in the event of sudden and extraordinary interruptions.

In some cases, due to the particularly critical conditions of the exchangers or of some of their components, extraordinary maintenance interventions are essential.

Benefits Maintenance Heat exchanger

- We can thus summarize the advantages of proper maintenance:

- Prevent the onset of holes or cuts on the exchange surfaces caused by corrosion;

- Keep the titanium micro channel perforated plateand therefore the project temperatures efficient;

- Avoid increasing the pressure drop due to encrustations or the presence of impurities.

Why heat exchanger maintenance is important

Why is maintenance of the heat exchanger important? Nothing is more disastrous than an unplanned interruption of work. Stopping production at an unscheduled time of the year produces considerable economic damage.

Scheduled maintenance of the heat exchanger can plan so as not to disrupt the company's regular production. Moreover, this avoids production losses in the event of a proven breakdown of unplanned machinery stoppage.

There is no escape. The seals age over time. However, if replaced in time, they can avoid causing losses and therefore damage.

Dirt can build up inside the pipes.

The dirt layer hinders heat transfer and degrades performance in titanium micro channel perforated plate. In many cases the pressure drops increases, creating problems in the pumping system.

It will improve the efficiency of the heat exchangers

Inside the heat exchanger, the deposit of solid material can occur, transport by fluids or precipitation products such as limestone. Moreover, this clogging of the tubes leads to a reduction in the heat transfer coefficient and, in conclusion, to a worse performance of the exchanger itself.

Increases the life of the machine

Scheduled maintenance of the heat exchanger increases the life span. This is because, with correct use, the machinery will more difficultly face an unexpected breakdown.

To know how a titanium micro channel perforated plate works, you need to know the parameters or know how to calculate them. Moreover, to solve a thermal problem, it is necessary to know some parameters, while others can calculate with the help of the latter.

Important parameters of micro channel perforated plate

The 7 most important parameters to know are:

- The amount of heat to be transferred (thermal potential);

- The inlet and outlet temperature from the primary and secondary side;

- The maximum head losses allowed on the primary and secondary side;

- The operating temperature;

- The maximum working pressure;

- The flow rate on the primary and secondary side;

- The types of fluids.

If the flow rate, specific heat and temperature difference on one side are known, the potential can be calculated.

Heat exchanger operation: thermal program

Moreover, it Indicates the inlet and outlet temperature of both fluids in the titanium micro channel perforated plate.

- T1 = Inlet temperature - hot side

- T2 = Outlet temperature - hot side

- T3 = inlet temperature - cold side

- T4 = Outlet temperature - cold side

Without taking into account the heat losses in the atmosphere, which are negligible, the heat lost (power) on one side of the plate heat exchanger is equivalent to the heat acquired on the other side. The power (P) express in kW or kcal / h.

Logarithmic mean temperature difference

The logarithmic mean temperature difference (LMTD) is the actual transmission force in the titanium micro channel perforated plate.

The thermal length (Θ) is the ratio between the temperature difference δt on one side and the LMTD

Θ = δt / LMTD

Moreover, the thermal length indicates the difficulty of an application from a thermal point of view. The density (ρ) is the mass per unit of volume and express in kg / m3 or kg / dm3.