The Emergence of Microchannel Heat Exchangers (MCHEs)

Energy conversion and consumption have always been important processes for sustainability and economic development. Environmental concerns such as air pollution led the engineers to implement clean energy resources to encourage practices of energy conservation. In 1981, Tuckerman and Peace first proposed the concept of microchannel heat exchangers (MCHEs) as an important component for processes to achieve energy conservation through enhanced heat transfer.

Basically, the job of heat exchangers was to transfer heat between two or more fluids for cooling or heating processes. These processing methods have influenced many industries. Since their inception, MCHEs have been extensively used to cool high-density electronic devices. Likewise, the transportation and chemical processing industries have used MCHEs for years. At present, their applications have been expanded to a much larger spectrum. The development of the solar energy industry and marine energy enterprises is highly dependent on a new form of printed circuit MCHEs.

The typical MCHEs possess a high surface-to-volume ratio and a high heat transfer coefficient. It is appropriate for use with fluids with high pressures.

Microchannel Heat Energy Exchangers (MCHEs)?

MCHEs present a difference between fin and tube heat exchangers. Their purpose is to improve overall heat transfer while conserving energy. Generally refrigerant or water drains through tubes whereas passes cross-current through the joined fins. This is one form of microfluidic technology which improvises flow sensors, micromixers, and heat sinks for chip cooling.

Fabrication of microchannels is an important aspect of the development of microfluidic devices. They are excellent and fast equipment for heating, cooling, and heat recovery. Besides connecting various devices, numerous industrial applications, biochemical technologies, genetics, and physics make use of microchannels to improve heat transfer. Leading manufacturers Stollpche and other Asian giants like Zhuolida are actively making microchannel plates on polymeric, glass, silicon, and other metallic substrates. Where biochemical and medical devices use polymeric and glass substrates, electronics, and mechanical-engineering-related applications require metallic and silicon substrates.

The plate heat exchanger is the main accessory on the main cooling machine. Microchannels are the next step in the development of a heat exchanger. Microchannel plates incorporate corrugated metal plates. The experts also call them to flow channel plates and heat exchange grooved plates. A Microchannel plate carries four corner holes for the two liquids for heat transfer to guide the fluid. The shape, size, and structures of microchannels vary depending upon the kinds of applications.

Usually, a heat exchanger comprises a stack of thin metal sheets attached together with diffusion bonding. The alternating slotted and unslotted sheets inside the stack include multiple parallel slots to form fluid flow channels.

Types of Microchannel Heat Energy Exchangers

The three main types of MCHEs or micro heat exchangers are:

Tube heat exchangers

A large number of small tubes in these heat exchangers are incorporated inside a cylindrical shell. The tubes are placed in the form of a bundle in the cylinder in fixed or a floating tube stack style. Such a positioning of the tubes eases out expansion and contraction of the tube bundle according to changing heat. It is easy to remove the tube bundles for necessary repair and maintenance.

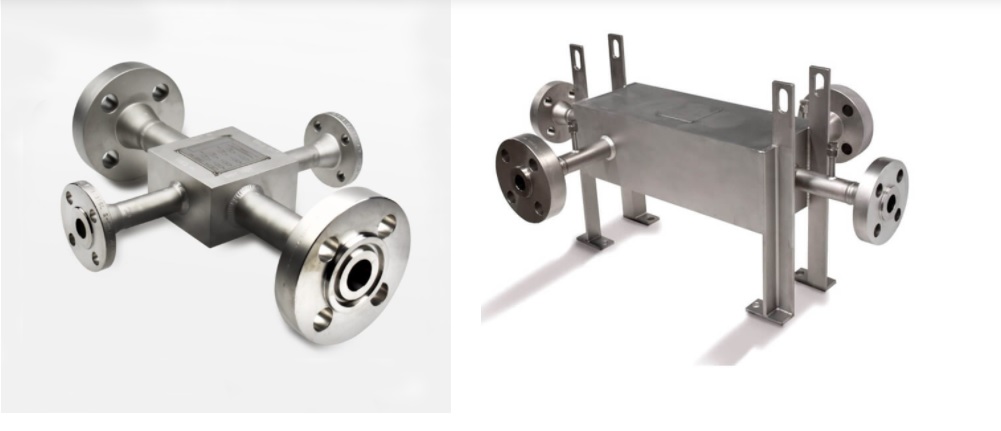

Microchannel flow plates

They work in pretty much a similar fashion as the tube heat exchangers do. However, unlike tubes, the micro heat exchangers use stacked flow plates. The compact stainless steel material of the flow plates makes them extremely useful for air conditioning in refrigerants. Ostensibly, they have a wide range of applications in food and beverage processing.

Air Cooled

Such heat exchangers are generally used in automobile vehicles and other applications where cool source water is not available permanently.

Benefits

Reduction of temperature difference

The goal of microchannel heat energy exchangers is to improvise the transfer of heat energy. The purpose is to potentially reduce the temperature difference between a refrigerant and the air.

More energy savings

The heat exchangers possess the capacity to lessen the airside pressure drop. As a result, they are able to deliver better energy-saving obtained through fan energy consumption.

Efficient handling of compact thermal energy transfer

MCHEs are largely used in sensitive applications which demand compact thermal energy transfer solutions. Stoll’s printed circuit heat exchangers play a wider role for solar thermal power to improve heat energy utilization.

Offshore oil and gas exploitation

The operating principles of printed MCHEs remain the same as in the case of freshwater use. The marine heat exchangers are resilient to corrosion caused by salty seawater. Their high-temperature resistance, high-pressure resistance, low-pressure drop, and efficiency make them popular with oil and gas exploration companies.

Minimize global warming risks

The microchannel heat energy exchangers require few materials and refrigerants. This is one great feature of MCHEs towards reducing the risk of global warming potential.

Impressive functionality of surface tension

The surface tension that comes into play due to microchannel heat exchangers, restrains the refrigerant liquid onto the surface of the microchannel. As a result, there is equal distribution of refrigerant liquid above and below the surface.

The microchannel heat energy exchangers etched in silicon substrate have been developed for various innovative applications. Their dimensions are selected to meet the performance requirements. The target optimization functions of MCHEs are pressure drop, temperature, and mass. The parameters set for optimization include porous fin’s layout, coolant flow, and MCHEs’ geometric dimensions.

Summary

The unique nature of a microchannel heat energy exchanger makes it a vital component in the energy conservation processes. The lightweight heat exchangers offer high heat transfer to meet increased energy demands while maintaining savings potential. The high-tech enterprises in Asia are beware of the importance of energy conservation. Stollpche Home - Channel Flow Plate - Products - Channel Flow Plate (stollpche.com) produces the best microchannels flow plates involving cutting-edge technology to ensure heat transfer. The micro heat exchangers are serving optimally in the commercial and residential air-conditioning systems while maintaining energy efficiency.