Plate-fin Type Heat Exchanger

For the last five decades, the aircraft industry has been using the plate-fin type heat exchanger for aircraft engineering. It has also been in use by chemical and cryogenics plants for more than 35 years. Apart from these, several other industries are also using plate-fin heat exchangers. Some other examples are motor cars and railway engines. Today, we will throw light on the structure and features of plate-fin heat exchangers. It should help you develop a better understanding about our today’s topic.

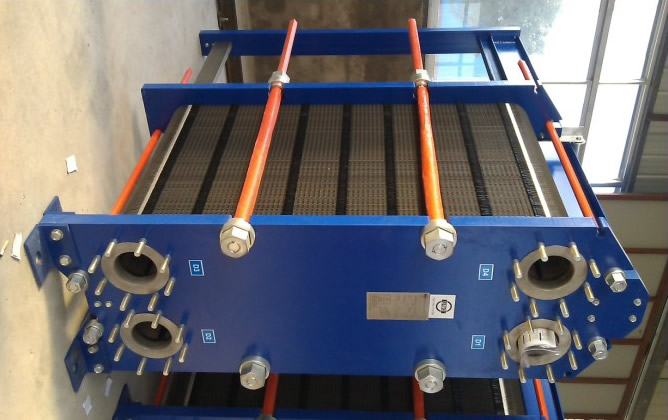

Structure of Plate-Fin Type Heat Exchanger

Plate fin heat exchangers (PFHEs) comprise a separation plate and corrugated fin which are brazed and stacked. PFHEs are lighter and more compact than other heat exchanger types. These heat exchangers are available from small to large sizes and made of materials, like stainless steel, and aluminum alloy, etc.

The structure of a PFHE consists of stacking flat plat (brazing sheet) and wavy plate (corrugated fin). Every single layer of a plate-fin type heat exchanger is an individual passage. If the material is aluminum, the filler material clads onto and integrates with the brazing sheet. The melting point of the filler material is low as compared to the core material.

The core bonds by heating the stacked core at a temperature where core material does not melt, but the filler material melts. There is a brazing sheet (flat plat) on top of the PFHE structure, and then a wavy plate (corrugated fin) followed by another brazing sheet. After that, there is another corrugated fin to complete the structure.

The product structure includes a core, distributor fin, brazing sheet, main fin, sidebar, and a side plate. There is also a nozzle and a header tank in the product structure. The structures of other types of the heat exchanger are different.

Features of a PFHE (Plate-Fin Heat Exchanger)

A plate-fin type heat exchanger is getting popularity among different industries for different unique features. Let’s take a quick look at the top features of the plate-fin heat exchanger.

1. Compact, Lightweight, and Improved Thermal Performance

Plate fin heat exchangers help you achieve lightweight and compact in general as compared to other heat exchangers. It is because the area of heat transfer is enlarged, so the area of heat transfer per volume also becomes large. It is true, especially in a gas-gas heat exchange procedure. The HE (heat exchanger) with an enlarged area of heat transfer becomes significantly lightweight and compact.

2. A broad selection of Fin Types

Various corrugated fin types are available to meet the needs of diverse customers. There are 300+ corrugated fin types available to choose from. Therefore, you can choose the most appropriate selection according to your project requirement. It is a luxury that is not available in other heat exchangers.

3. Multi-Fluid Heat Exchange

The plate-fin heat exchanger structure allows for multi-fluid heat exchange due to its specific structure. Therefore, it helps in reducing installation space and piping. The best thing about a PFHE is that up to fifteen fluids are possible.

4. Durability

A plate-fin type heat exchanger is durable and ensures superior air-tightness. Corrugated fins (wavy plates) are brazed with flat plates (brazing sheets) and configure the integrated structure. PFHEs enlarge the area of heat transfer and also withstand higher internal pressure, providing superior durability. Therefore, you can choose plate-fin heat exchangers for sound air-tightness and mechanical reliability.

5. Reliability and Quality

Plate fin type heat exchangers are known as the most reliable and top-quality heat exchangers than other types. PFHEs are the most commonly used types of heat exchangers across the world in various industries for quality and reliability.

6. Versatility in Material Selection

You can choose from several material types, according to different conditions and fluids. The most common materials available are aluminum alloy, nickel alloy, titanium alloy, and stainless steel. Therefore, the versatility in material selection makes plate-fin heat exchangers a better option than other heat exchanger types.

As said before, a plate-fin type heat exchanger has its use in different industries. The most popular industries that use PFHEs include aircraft engineering, chemical plants, automotive industry, and cryogenics plants, etc.

Here are the most common examples for plate-fin heat exchanger use with different materials:

- For air separation (aluminum alloy)

- Industrial machine oil cooler (aluminum alloy)

- High-speed train (aluminum alloy)

- Fuel cell heat exchange (stainless steel)

- Nine fluid heat exchange for plants (stainless steel)

- The heat exchanger (high pressure) for the plant (stainless steel)

- Gas turbine recuperator (stainless steel)

From the above-listed examples for use, you can understand how versatile plate-fin heat exchangers are in material selection.

Advantages of Plate Fin Heat Exchanger

Plate fin heat exchangers are popular heat exchangers for various reasons. Here are the top advantages of using plate-fin heat exchangers for your project:

- Increase in BTU, resulting in higher rates of heat transfer.

- Fewer shadow areas and edges to get debris. It minimizes the coil fouling, resulting in a straightforward cleanup.

- Less fouling and low air turbulence. It results in the lower drop of air-side. It is a significant advantage for different industries, such as Oil & Gas, Food Processing, and Pulp & Paper.

- Plate fins have approximately 40% additional secondary area of fin surface.

- It possesses more capacity as compared to the same configured coil.

For the above advantages, PFHEs are becoming increasingly popular among different industries for different applications.

Conclusion

A plate-fin type heat exchanger has been in use for more than 50 years and a top choice for different industries. The most prominent industries using PFHEs, including the aircraft industry, choose plate-fin heat exchangers over other types for various reasons. We have also discussed the structure of a PFHE to help you know its anatomy. This article also covered the top features and primary advantages of plate-fin heat exchangers in this article. Therefore, we hope now you can understand the significance and reasons behind the popularity of this heat exchanger type.

We will discuss the use cases of plate-fin heat exchangers in our next articles. Keep visiting up or contact us, anytime, for further information on this topic.