What is a Printed Circuit Heat Exchanger?

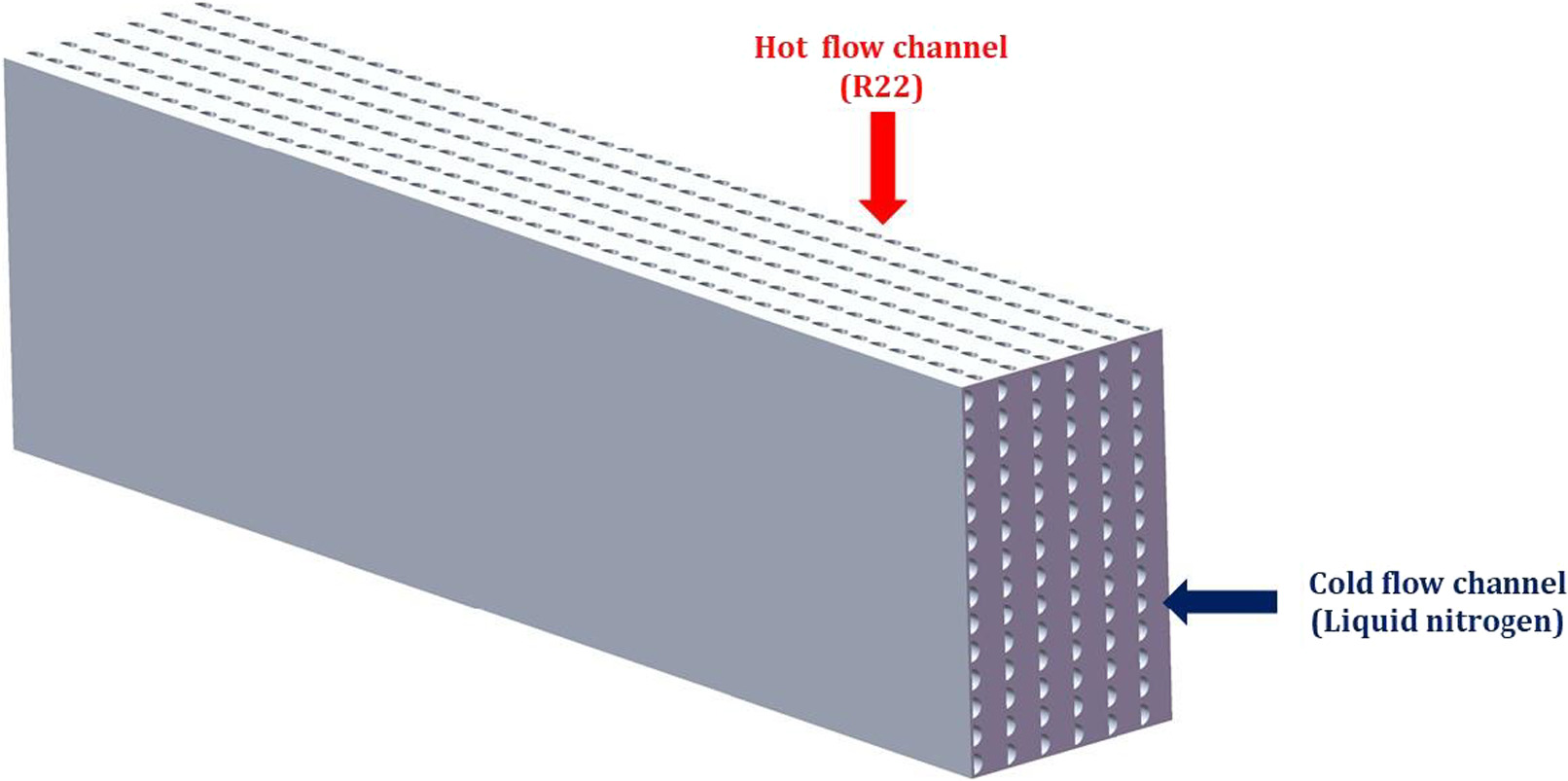

A printed circuit heat exchanger is a device that facilitates the co-joining of different materials. This exchange is known as diffusion bonding. The printed circuit heat exchanger manufacturer specializes in building-high quality machines that have no weld and fixtures.

To make sure, the printed circuit heat exchanger manufacturer makes use of either surface of the heat exchanger to create a solid bond. This allows the pressure to flow from both sides to optimize results. The printed circuit heat exchanger manufacturer works optimally in order to deliver the required amount of heat length as well as compression drop.

Usually, the design of these printed circuit heat exchangers is quite complicated because it replicates the flow of the configuration present on the sheets through chemical etching. Typically the design carved in these materials works under very specific shapes according to the requirement of the client. They need to fulfill the thermal and hydraulic features of the process.

The Adverse Effects of Heat on Printed Circuit Boards

Opposing to the common belief regarding printed circuit boards, they are in grave danger of heating up excessively. Many researchers are working on this very problem to increase the efficiency of printed circuit boards under heat.

Some have even developed some contemporary styled circuit boards that give great performance even under high temperatures. Despite the fact that their development is taking place under great scrutiny, they too have a limit to what they can bear.

After some point in time, the temperatures get out of control and elevate. Under elevated temperatures, they are unable to bear the pressure and can break down under stress. Thus, it is very important to consider all the mishaps. They can happen to the printed circuit board under elevated temperatures.

The following are some of the adverse effects that can ruin a circuit board because of heating. This way we can come up with certain techniques to encounter the overheating of these boards. Hence, we can take precautionary steps beforehand. Here are a few hostile effects of heating on PCB that includes the co-relation between PCB design and heat accumulation, ill-treatment of heat generation, and overindulgence of heat in printed circuit boards.

The Co-relation between PCB Design and Heat Accumulation

If you think wisely, you can easily correlate the relationship between printed circuit board design and the accumulation of heat within. The accumulated heat can heavily influence the design as well as the manufacturing of printed circuit boards.

This effect is harmful to the efficiency and optimal performance of the circuit boards. It also sucks out the trustworthiness and integrity of the working of these circuit boards. Moreover, it affects many other features in the design of the circuit board.

There are many characteristics involved when designing a printed circuit board to make it efficient enough to bear all the heat at elevated temperatures. The size of the PCB matters a lot since a smaller size can heat up very easily rather than a PCB that is bigger in size. Additionally, the power rating also affects the heating up of the PCB.

The cost of manufacturing might increase in the initial stages when you are trying to come up with ways to fight the accumulating heat. But if not taken care of with precautionary steps, it can cost a lot later. The maintenance cost can keep on accumulating. This is a definite thing that heat can cause much dis-functionality in the board hence it is important to deal with this problem wildly from the start.

Another way that heat can impact negatively is the functionality of the device they are part of. Some applications may require the device to heat up more often than others. Hence it is important to judge the criteria at which the device is going to perform in the later stages and design it accordingly.

Treating Heat Generation Beforehand

What is more stable than treating heat generation beforehand? This is why we need to consider the glass transition temperature when making use of printed circuit boards in very high temperatures. The glass transition temperature is the point at which the polymers or materials used can become solid and breakable like glass.

Many manufacturers have developed some benchmarks in which they define how to incorporate some materials in similar applications. Although there is no firm way of deciding which polymer goes with which kind of application, there are some benchmarks set after much experimentation under different temperature levels.

In simple words, when applying printed circuit boards in applications that can reach a temperature of more than 130 degrees Celsius, it is feasible to use polymers that have a high level of the glass transition temperature. Some of the common polymers/resins can accommodate high temperatures. They include Shengyi S 1000, ARLON 85 N, ISOLA IS 410, ISOLA IS 420, and ITEQ IT 190 A.

Overindulgence of Heat in Printed Circuit Boards

It is very important to control the overindulgence of circuit boards. Some common methods include radiation, convection, and conduction. Radiation allows the heat to escape in the form of electromagnetic waves. Convection allows the heat to emit in the form of liquid. Conduction emits heat when it comes in direct contact with the source of heat emission.

Stollpche can provide very stealthy solutions for heat-accumulating problems that can adversely affect the printed circuit boards. They have a very high-tech team that provides reliable solutions to heat generation problems in PCBs. Plus, they have their own range of high-temperature enduring PCBs.

Summary

As discussed in the article, an accumulated amount of heat can adversely affect printed circuit boards. It can be damaging to their heat exchangers. It is important to come up with remedial steps that can prevent the damage from occurring beforehand. You can find many reliable printed circuit heat exchanger manufacturers with reliable products. They can help protect the device and keep it running for a very long time thus making it durable.