Under this premise, there are two types of heat exchangers

Direct top quality printed circuit heat exchanger. In this type of exchangers, the media, although not mixed, are in direct contact. For example, we can find this type of exchangers in cooling towers, where the water is sent through direct contact with the air.

Indirect top quality printed circuit heat exchanger. These exchangers separate by a wall through which heat transfers. We can find them of various types: plate, shell and tube, spiral, etc.

In most cases, the plate heat exchanger is the most efficient heat exchanger since, despite being of the indirect type, thanks to the turbulence generated by the corrugated plates in the different fluids, its heat transfer increases.

And keep the properties of each circuit intact. In general, it offers the best solution to thermal problems, providing the widest pressure and temperature limits within the constraint of current equipment.

Different exchangers have different performances

There is a common misconception in the market that assumes that all plate heat exchangers are similar in performance, regardless of brand. However, nothing could be further from the truth, since there are design features that can have a great impact on top quality printed circuit heat exchanger operations, such as:

- Reduced installation and maintenance costs.

- Reduction of energy costs.

- Decreased downtime and unforeseen stops.

- Increased staff security

How top quality printed circuit heat exchanger works?

The top quality printed circuit heat exchanger is a device designed to transfer heat between two fluids, being these in contact or separated by a solid barrier. These are essential components in air conditioning or refrigeration systems, air conditioning, energy production and chemical processing.

To easily understand the operation of the heat exchanger, we can take the radiator of any vehicle as a reference. The engine heats the cooling fluid.

The latter’s cool contact with air currents, thus reducing the temperature of the former after circulating inside it.

Heat Exchanger Uses

Top quality printed circuit heat exchanger uses for the following uses:

- Raise the temperature of a fluid thanks to a hotter one.

- Cool a fluid using another with a lower temperature.

- Bringing a fluid to the boiling point by the action of a second with higher temperature.

- Condensing gases using cold fluids.

- Bring a certain fluid to the boil while condensing another hotter gas.

Types of top quality printed circuit heat exchanger

When classifying the different types of heat exchangers, different criteria can be taken into account. If we analyze the degree of contact between the fluids involved, they can group into two large blocks:

Direct contact heat exchanger

In direct contact exchangers, heat transfer carries out by means of a physical mixture of the fluids involved in the process. The two streams are easily separable after energy exchange.

Cooling towers are direct contact exchangers, which are responsible for removing heat from a stream of hot water, by means of dry and cold air circulating in the system.

Indirect contact heat exchanger

In indirect action mechanisms, on the contrary, there is no direct contact between the fluids, they do not mix. They separate by solid elements, by a space and even by a period of time. Heat transfers by convection or conduction through the separating wall.

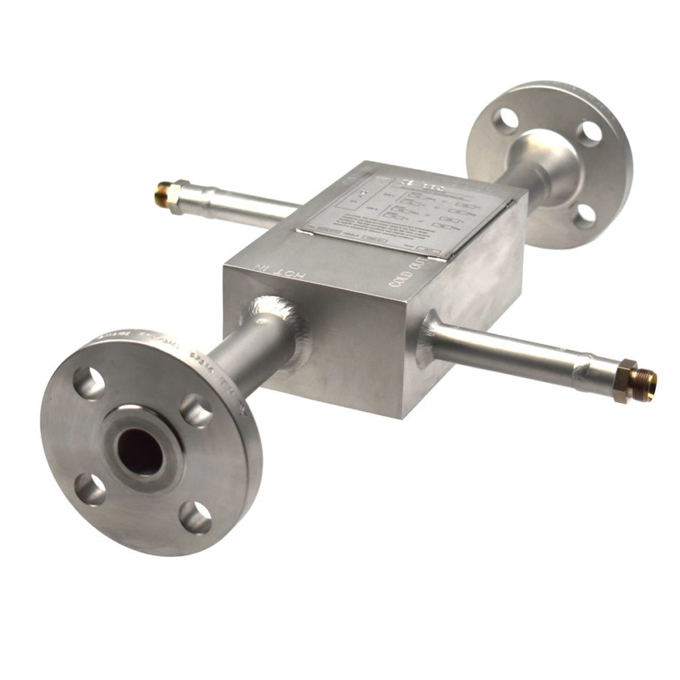

Indirect contact top quality printed circuit heat exchanger can be concentric tube or double tube, shell and tube, plate, compact, regenerative, etc.

Double tube equipment is the simplest that exists. They are made up of two concentric pieces of different diameters. One of the fluids circulates inside the smaller one and the other does so through the annular space between the two tubes.

The following topic will give you an initial idea of how it works?

Shell and tube exchangers widely use in industry. As the name suggests, its basic components are a shell and a multitude of tubes.

For their part, the plate systems assembles bases on a succession of metal sheets, all assembled on a frame and separated by joints fixed to a steel shell. The connection between the sheets allows a certain fluid to flow between the first and second, another between the second and third, and so on.

Do you know the specific operation of a top quality printed circuit heat exchanger? Basically the basis of operation is that the hot and cold fluids exchange their heat with each other through the corrugated plates, but how is this possible?

Operation of the plate heat exchanger

As can be seen, the total liquid that passes through the exchanger divides into equal parts bases on the number of plates in the exchanger. Every two plates a circulation channel generates through which one of those portions of liquid flows.

Thanks to this mechanism, and to the corrugation of the plates, the circulation speed is notably increased, creating a turbulent flow that reduces the risk of fouling while optimizing heat exchange, in such a way that the fluid will achieve 100% flow rate. It is temperature at the end of the path of each plate.

Three important aspects to take into account regarding the Plate Heat Exchanger

Ultra-thin plates with top quality printed circuit heat exchanger coefficient are more efficient.

Current heat exchangers require very little space for mounting, compared to the old shell and tubes.

In addition, they are easy to maintain because in case of fouling, their disassembly and cleaning is very simple and fast.

Plates with exchanger gaskets

Plate heat exchangers make use of corrugated plates arranged between a mobile pressure plate and a fixed pressure plate. Although, the corrugate parameter will depends on the type of fluids, the maximum pressure is whether there dissolve solids in circulation.

However, it is the unique corrugation pattern embossed on each top quality printed circuit heat exchanger that is capable of producing a higher heat transfer rate.

Top of the line Plate Heat Exchanger design ensures maximum long-term customer satisfaction

- The high quality of the gaskets allows a tight seal and quick and easy maintenance.

- Double seal that minimizes the possibility of both fluids mixing.

- Detection of leaksthat, in case of breakage of the joint, diverts the leak to the outside.

- Zinc bath that guarantees a long life to the equipment.

- Greater comfort in assembly and disassemblythanks to the fact that all the parts thread and that the adjustment can be made from the fixed front plate.

- Easily expandableto suit your needs.

Another advantage of the top quality printed circuit heat exchanger is that. Since almost all the material uses to exchange heat. Its effective transfer capacity is very high on a small surface. Furthermore, being five times smaller, it has the same thermal capacity as a shell and tube heat exchanger.