What the process of Sizing a mini micro channel porous thin plate?

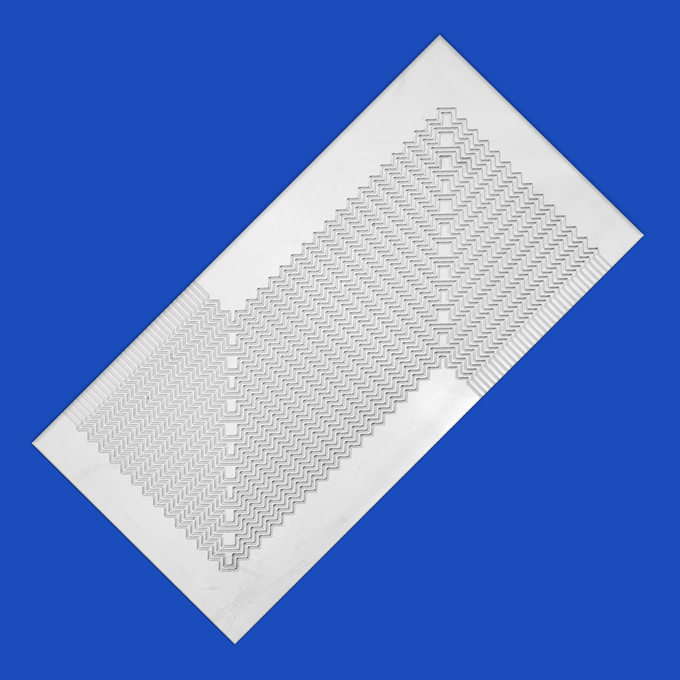

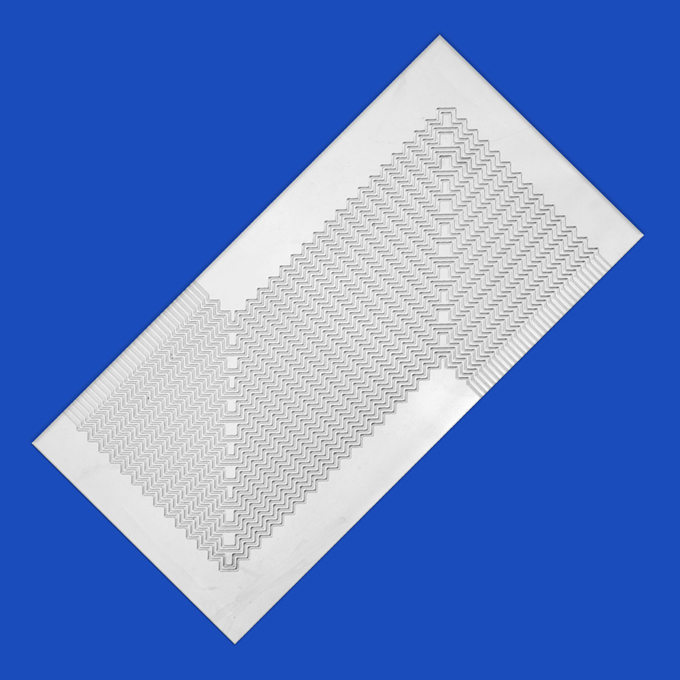

Mini micro channel porous thin plate holds fluids that is the transmission of heat between a wall and a fluid in motion. The conduction or natural transfer of heat through plates, walls and tubes, a phenomenon directly related to the principle of thermal agitation without movement of matter.

Phases to size a mini micro channel porous thin plate

The sizing of a micro channel plate is carried out in three stages:

1.-Selection of the best technology

The technological choice refers to the selection of the thermal program to the nature of the fluids, to space and maintenance limitations, and to the use that the client will give them.

All this as a whole will allow defining the best type of exchanger and the materials to be used, without forgetting that, on occasions, the obligation to use specific materials will decisively include the type of exchanger.

2.-Thermal dimensioning

(a) Thermal program validation.

Once the mini micro channel porous thin plate has been chosen, it is time to proceed with its dimensioning, that is, determine the thermal power, the surfaces and the geometry. To do this, first of all, the data of the thermal program must be passed in a loop with the following three formulas:

Hot = P cold

P hot = Q x Cp x ∆ T hot

Cold = Q x Cp x ∆ T cold

- P: power (expressed in KW or KCal/h)

- T: temperature (expressed in ºC)

- Q: flow rate (expressed in kg/h)

- △t: Tenin –Tout (expressed in °C)

- Cp: specific heat for mini micro channel porous thin plate(expressed in KWh/Kg/°C)

(b) Calculation of the exchanger surface

The first step will be to define the LMTD or Logarithmic Mean Temperature Difference (△TLM), which is the logarithmic mean of the temperature clamps at each end of the exchanger.

∆TLM = [(Te1 – Ts2) – (Ts1- Te2)] / [ln (Te1 – Ts2) – Ln (Ts1 – Te1)]

- Te1: cold entry

- Te2: Hot starter

- Ts1: T cold outlet

- Ts2: T hot outlet

Once the ∆TLM has been calculated and the total exchanged power has been estimated.

The exchanger can sized using the following formula

Total P exchanged = K x S x ∆ TLM

- Total P exchanged

- K: exchange coefficient expressed in KW/°C/m2. It depends on the exchanger and calculates by the manufacturer.

- S: mini micro channel porous thin plateexchanger surface in m2

Now we are left with two unknown data, K and S. We will have to calculate K to estimate the surface of the exchanger.

(c) Calculation of K and fouling factor

The exchange coefficient of an exchanger determines bases on the following formula:

1 / K fouling = 1 / h1 + 1/h2 + e/λ + R fouling

- H1 and h2: local corrective exchange coefficients calculate bases on correlations and dimensionless numbers such as Reynolds (Re), Prandlt (Pr) and Nusselt (Nu).

- e: wall thickness in m

- λ: thermal conductivity of the wall in W/°C/m

- Resoiling: resistance due to wall fouling

Obtained the K value, we can calculate the surface and the dimensions of the mini micro channel porous thin plate exchanger.

3.-Calculation of load loss

Any fluid that is in motion suffers energy losses due to:

- The frictions on the walls (regular load losses) or,

- Route accidents (singular load losses) such as chicanes.

This energy loss, which expresses as a pressure difference (△P), must compensate to allow the fluid to move.

Thus, once we have learned how to size a micro channel plate, we will calculate its load losses with different correlations determined based on the characteristics of the mini micro channel porous thin plate exchange surfaces.

Once these losses have been calculated, we will start a reiteration process from step 2, until we get the desired power to be equal to the power obtained.

The performance of a micro channel plate

Performance and efficiency is not exactly the same thing. In this case, the performance is equal to the absence of loss, so that the efficiency of a mini micro channel porous thin plate is equal to the performance resulting from the following formula:

Power that I recover / Power that I could recover

The yield of 1 is an impossible infinity to reach. In most cases, the performance is set from the request by the client itself, since it induces the power and temperature needs of the client's application.

Brazed Plate Micro channel plates

First of all, brazed mini micro channel porous thin plate (BHE) has stainless steel plates. They are welded with copper in the case of the CB model, which gives them high resistance and thermal efficiency.

Designed for refrigeration and A/C work, BHEs are compatible with HCFC, HFC, HC and CO2 refrigerants. Also, its temperature range is -196°C to 225°C; and they have different nominal pressure possibilities, up to 130 bars, depending on the model.

The advantages of this type of exchangers are that they are extremely compact, light, and easy to install. In addition, they have a low refrigerant charge, and have a safe control of the capacity of the evaporators thanks to the double refrigerant circuits and great heat recovery capacity.

Mini micro channel porous thin plate are suitable for evaporation, condensing, gas cooling, heat recovery, and suction gas plate, oil coolers in refrigeration and air conditioning applications.

Removable plate micro channel plates

We also highlight the range of removable plate micro channel plates, or with gasket (PHE – Plate Micro channel plate), which include versions for hygienic, refrigerant, pure and corrosive fluids in combination with refrigerators.

It has an operating pressure of up to 25 bars; and an operating temperature up to 180°C. Flow rates are up to 680 m3/h.

Conclusion mini micro channel porous thin plate

This type of exchanger works by approximate temperature, and saves space and energy compared to other exchangers. Its resistance to wear is optimal since it does not form scale with untreated water and prevents corrosion. It features long-lasting, glue-free gaskets that easily replaces on site.

Mini micro channel porous thin plate are suitable for pressure regulators, free cooling, protection from seawater and dirty water from cooling towers, combined with A/C coolers and boiler installations.