A printed circuit heat exchanger production is a structure whose purpose is to change the temperature of gases or liquids passing inside it. Heat exchangers can heat and cool streams and processes are often accompanied by evaporation and condensation.

Such systems design for heat transfer between streams, one of which heats and the other cooled. It does not matter which task is a priority - heating or cooling. The principle of operation of heat exchangers bases on heat exchange between two media.

Types of heat exchange units

Superficial

In this case, the coolants are on both sides of the wall separating them through which heat is exchanged;

Mixers

The design of the printed circuit heat exchanger production of this type provides direct mixing of heat carriers. Such units are efficient, they require less metal. The disadvantage of such installations is the limited scope, as it is not always allowed to mix streams.

Regenerative

The device of the printed circuit heat exchanger production provides heating of streams by means of the special tool which is alternately heated and cooled.

Types of heat exchangers by purpose

Heaters

Heating of one stream carries out due to cooling of another. Such installations are economical, as the need for heat supply from the outside reduces;

Cooling installations (refrigerators)

The flow is cooled using a special substance (chilled water, air, propane). The main purpose of such units is cooling; heating with a special substance is a side effect.

A number of requirements are set for industrial heat exchangers

The heat transfer coefficient of materials should be as high as possible; The design should take up as little space as possible and consume a minimum of materials and fuel;

Cleaning of the printed circuit heat exchanger production should carry out easily and quickly, thus in the course of work the design has to be dense and reliable.

The same requirements apply to domestic heat exchangers.

According to design features heat exchange units are of the following types

Tubular

This is the simplest type of heat exchanger. These devices are low cost, small size and high efficiency. Designs of this type use in the chemical industry. The design is made in the form of a cylinder in which a number of tubes place.

The cylinder body is hollow, it contains coolant. The cavity with the tubes fills with another substance. Such, printed circuit heat exchanger production uses as condensers. In this case, the coolant flows through the tubes, and steam enters the cavity of the housing;

"Pipe in a pipe";

The advantage of this type of exchanger is its light weight and size. More than two heat carriers can exchange heat. The unit can contain an unlimited number of plates;

Structure of printed circuit heat exchanger

Such structures consist of two sheets made of steel and twisted into a spiral. The sheets form valves. The coolant enters the center of the structure and passes along the perimeter, the contact medium moves in the opposite direction. The device protects by a housing that removes for cleaning;

The basis of this type of printed circuit heat exchanger production is the spraying of heated liquid in the upper part of the tank. When sprayed, the liquid loses some heat.

The air flow that passes at the bottom of the structure absorbs heat. The disadvantage of this device is its huge size, which reaches a height of 100 m.

Heat transfer can occur in different from structural point of view devices. When choosing a design bases on the properties of the coolant and the contact medium, the scope of the device.

CONSTRUCTION OF THE HEAT EXCHANGER

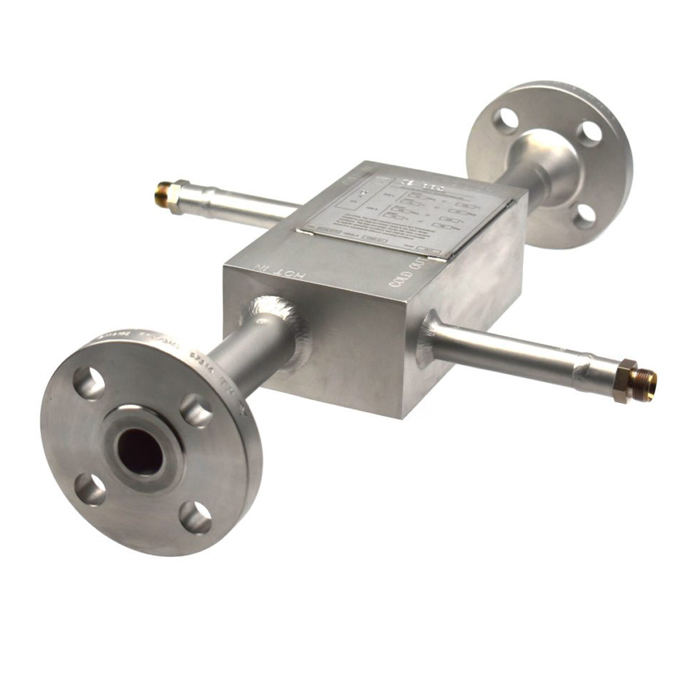

The pipe-in-pipe printed circuit heat exchanger production uses for household purposes and in industrial enterprises. The design consists of two pipes of different diameters, one inside the other. The liquid to heat or cool is in direct contact with the coolant.

Heat exchange tubes place along each other. The difference in their diameter allows the coolant to move freely. The heat exchanger works on the principle of heat exchange between the contact fluid and the coolant.

Heat exchangers are easy to operate

They use in the oil, gas, chemical and food industries. This is due to the reliability of the device, tightness, ease of maintenance. Industrial heating of the above type is optimal for large rooms.

The unit consists of several links. Fluid supply carries out by means of branch pipes. The design is made in the form of a spiral. Straight sections place one above the other in series. The inner pipe connects by special arches.

Printed circuit heat exchanger production for heating is often uses in country houses. But the heat exchanger is not so easy to make with your own hands.

This requires a professional calculation of the technical parameters of the device, which is impossible without some knowledge. The process of assembling the unit is much simpler than its calculations.

Diameter for printed circuit heat exchanger production

Two sections of pipes of different diameters select for self-manufacturing of the device. It is better to use thin-walled elements, so the heat transfer rate will increase significantly. The only factor that affects the wall thickness is the fluid pressure.

It is important that the structure not deforms. The gap between the pipes placed one inside the other should be 1.5 mm - 3 mm on all sides. The length of the inner tube should be less than the outer. T-tees must install at the ends of the outer pipe.

It is better to make independent heat exchangers from copper elements. Steel pipes may be an alternative, but in this case the efficiency of the device will decrease.

ADVANTAGES OF "PIPE IN PIPE" HEAT EXCHANGERS

The advantages of printed circuit heat exchanger production base on the design features of the device. The movement of liquid on the unit occurs at the optimal speed for its heating or cooling. The coolant and the constant fluid are in the right balance.

This achieves by selecting the optimal diameter of the elements. Heat exchangers for heating must design according to all the rules.

The advantage of the unit is that it uses a variety of substances. Water, steam, gas, and any viscous liquids act as contact media.

Conclusion

The printed circuit heat exchanger do not require special care, they do not need maintenance. Cleaning the heat exchanger carries out in minutes. This achieves by the sections connect by detachable flanges. The design is easy to disassemble.

This also applies to its repair. The failed section easily dismantles and replaces with a new one or repaired.