Perforated flow plate, everything you need to know

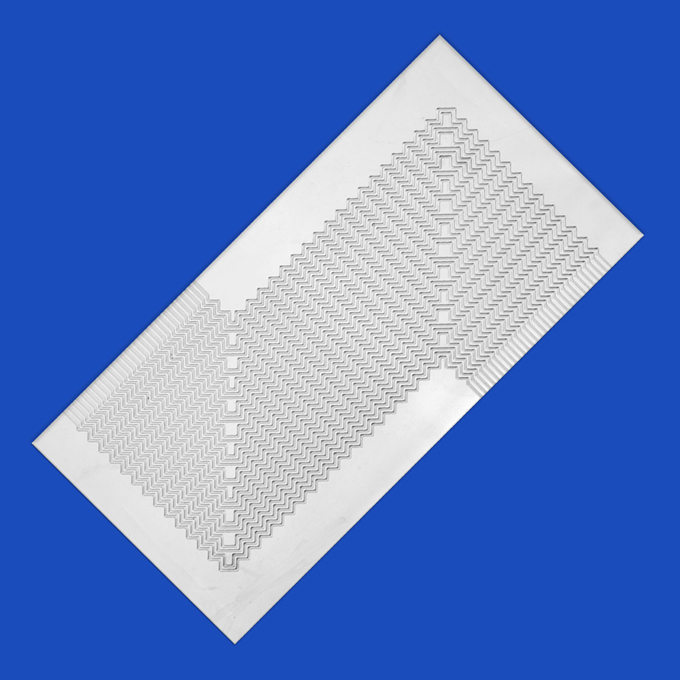

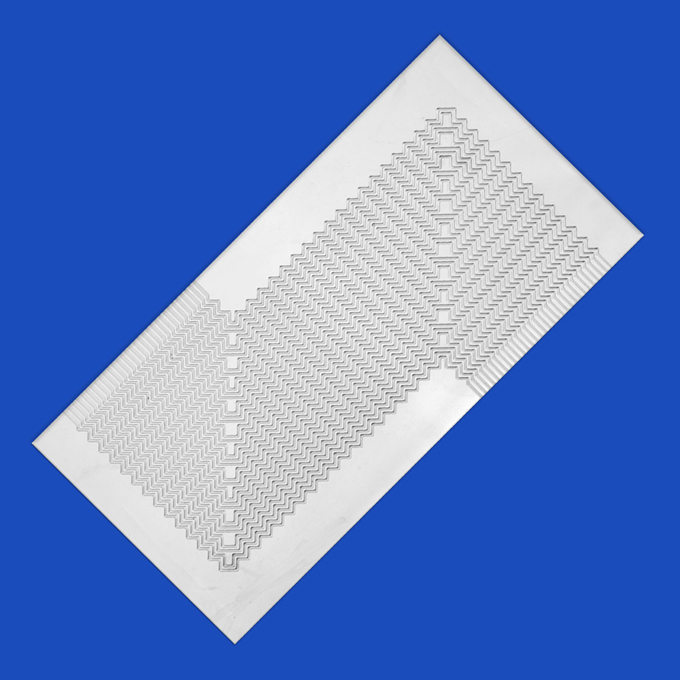

Firstly, the zigzag micro channel perforated flow plate is good to use to heat or cool a medium by transferring heat. It is therefore a system that transfers heat from a hot fluid to a cold fluid, and which is good to use in a whole series of sectors.

Typically, plate perforated flow plates are good to use

In them, two fluid streams of different temperatures exchange heat through raised surfaces placed next to each other. The plate perforated flow plate therefore consists of a sequence of corrugated plates, separated from each other by elastomeric gaskets. As well as, the interspace that creates between two plates is the channel in which the fluid flows:

The hot fluid and the cold fluid pass through the zigzag micro channel perforated flow plate in alternate channels. In this way, each plate is always in contact with both the hot fluid (on one side) and with the cold fluid (on the other side).

Where the corners of the plate locate, small holes allow the inlet and outlet of fluids.

Zigzag micro channel flow plate provides more efficient thermal performance

As a rule, liquids run counter -current through the perforated flow plate, which provides more efficient thermal performance and allows for a very close temperature approach (the difference in temperature between the outgoing process medium and the incoming service medium).

When the fluids are thermo sensitive or viscous, however, the flow can be good to use in co-current mode: in this way, the risk of overheating or freezing of the supports minimizes.

The zigzag micro channel perforated flow plate are available with various pressing depths, zigzag pattern angles and various corrugation shapes, and are all designed for optimum performance. In fact, each type of plate is suitable for a specific use. Our thermal design engineers can help you design and select the model and configuration that best suits your needs, so you can get the best thermal performance with minimal pressure drop.

Perforated flow plate, what is it for

Moreover, the applications of a zigzag micro channel perforated flow plate are different. Typically it is good to use to heat, cool, recover heat, promote its evaporation and condensation. Industrial gasket plate perforated flow plates allow you to design and configure such instruments for simple as well as very complex tasks, both in terms of performance and documentation.

The importance of sizing

Furthermore, the sizing of a zigzag micro channel perforated flow plate depends on its ability to satisfy the need for which it was designed (and to solve any problems that may arise). As well as, to carry out a correct sizing it is necessary to know the type, flow rate and working temperatures of the two fluids involved, in addition to the pressure drops allows in the two circuits.

The thermal power exchanger

Eventually, the thermal power of an exchanger depends on the thermodynamic conditions of the two fluids. When a technical problem occurs, some parameters must be known while others can calculate with the help of the latter. The seven main parameters are:

- the amount of heat to transfer (thermal potential)

- the inlet and outlet temperature from the primary and secondary side

- the head losses allowed on the primary and secondary side

- the maximum operating temperature

- the working pressure

- the flow rate on the primary and secondary side

- the types of fluids

Further, if the flow rate, specific heat and temperature difference on one side are known, the potential can calculate.

The thermal program

The thermal program indicates the inlet and outlet temperature of both fluids in the zigzag micro channel perforated flow plate:

- T1 = Inlet temperature - hot side

- T2 = Outlet temperature - hot side

- T3 = inlet temperature - cold side

- T4 = Outlet temperature - cold side

Power and Logarithmic mean temperature difference

Subsequently, the heat lost on one side of the plate zigzag micro channel perforated flow plate is equivalent to the heat acquired on the other side: this is the power, which expresses in kW or kcal / h.

The logarithmic mean temperature difference (LMTD) is the actual transmission force in the perforated flow plate.

Cooling down

Secondly, in cooling applications, the thermal program needs precise approaches according to the different temperatures (thermal length). We speak of high length in the presence of values of Θ> 1 characterized by:

Scope and how flow rate expressed

The flow rate can be expressed by weight or by volume. The flow units per weight are in Kg / s or kg / h, the flow units per volume are in m3 / hol / min. To convert volume units to weight units, you need to multiply the volume flow by the density. The maximum flow determines which type of zigzag micro channel perforated flow plate is appropriate for a particular purpose.

Alfa Laval plate perforated flow plates can be good to use for flow rates from 0.05 kg / s to 1400kg / s. In terms of volume, this equates to 0.18 m3 / h - 5000 m3 / h in a water application. Moreover, if the flow rate exceeds these values, it will be possible to split the flow into several units in parallel.

Pressure drops

The pressure drop (Δρ) is inversely proportional to the size of the plate perforated flow plate. If it is possible to increase the allowable pressure drop and accept higher pumping costs, the perforated flow plate will be smaller and less expensive.

Specific heat

Specific heat (c ρ) is the amount of energy needed to increase 1 kg of substance by one degree centigrade.

Viscosity .Viscosity measures the ease of flow of a liquid. The lower the viscosity, the easier it is to slide. Viscosity expresses in centipoise (cP) or centistoke (cSt).

In addition, a zigzag micro channel perforated flow plate; you can take advantage of the benefits of small differences in temperature and plate thickness. The alpha values produce by very high turbulence and the fouling factor is generally very low. This defines a coefficient k which, under favorable circumstances, can be in the order of 8000 W / m 2 ° C. With traditional shell and tube perforated flow plates, the coefficient k will be lower than 2500 W / m 2 ° C.

To minimize the cost of the perforated flow plate it is necessary to consider

- Lastly, the pressure drop: the higher the allowable pressure drop, the smaller the required heat exchange surface.

- LMTD: The greater the temperature difference between the fluids, the smaller the size of the zigzag micro channel perforated flow plate.

- long plates, therefore more time required for liquid cooling

- low pressure, therefore worse distribution of the liquid to cool