What is a Plate Heat Exchanger?

World leader printed circuit heat exchanger is a type of heat exchanger that uses metal plates to transfer heat between two liquids. The advantage of plate heat exchangers over other types is that the heat transfer is better than others.

This is because the liquid will be exposed to a much larger surface area. The liquid will spread throughout the sheet and greatly increase the speed of temperature change.

Plate Heat Exchanger Type

Plate heat exchanger can be classified according to the connection of the plates into 2 types as follows:

- Brazed plate heat exchanger

Each sheet in small plate world leader printed circuit heat exchanger will be connected to each other. It has high heat transfer efficiency Small and compact, suitable for use in small, cheap places, but there are disadvantages. Each sheet cannot be removed for cleaning. This is suitable for small heat exchangers and ventilation applications.

- Gasket plate heat exchanger

Plate heat exchangers use gaskets between plates. It is popular for commercial use because each plate can be removed for cleaning. It is suitable for medium and large heat exchangers and ventilation applications.

How does world leader printed circuit heat exchanger work?

Bringing several heat transfers plates to line up by giving fluids pass in the gaps of each sheet alternately but the sheet will have a gasket which is pressed from the frame as a seal. Therefore, the two fluids do not come into direct contact with each other. Therefore, heat transfer takes place through the cross-sectional area of each sheet.

Key Components of Plate Heat Exchanger

It consists of a set of plate heat exchangers. It has a wavy shape and is common as a medium for heat exchange of two-sided fluids. This set is mounted between the front frame and the compression frame world leader printed circuit heat exchanger with another set of bolts to secure it.

This can remove the latch for inspection and cleaning of each sheet has a gasket around the sheet acting as a shield between the sheets.

It determines the flow direction of the fluid to flow alternately between the plates. Moreover, it prevents the two fluids from mixing. Determination of the number of sheets common depends on the flow rate. Physical properties of fluids pressure drop and desired inlet and outlet temperature with inlet and outlet pipes. It comes on the front frame but may be on both frames

Plate Heat Exchanger, what are the advantages and disadvantages?

World leader printed circuit heat exchanger is commonly common in refrigeration systems. Small-Medium (HVAC) Food Industry To increase or decrease the temperature in thermal processing systems, in-line pasteurization, concentrating and UHT systems and are common in industry. Similarly, it comes in power plant chemistry paper industry steel industry, etc.

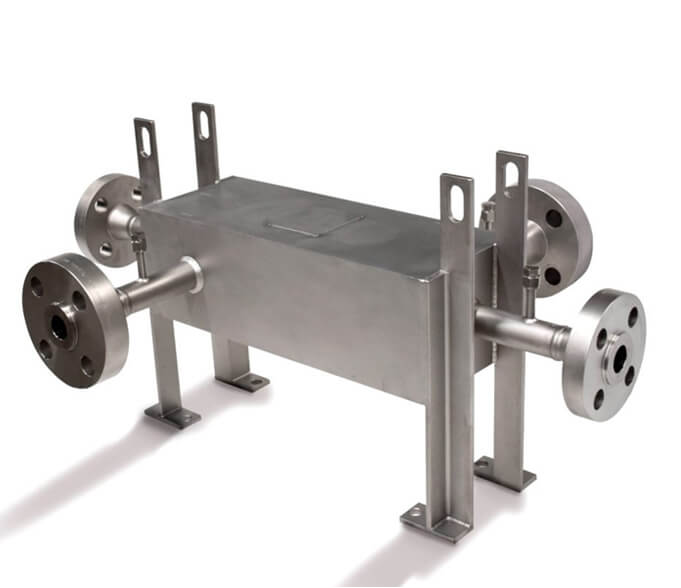

Shell and tube heat exchanger are a heat transfer tool from a kind of fluid to another fluid which will act like Evaporator in the cooling system. And will have an external structure similar to a condenser and an internal structure similar to an Evaporator is a baffle inside the tube.

What is Shell and tube world leader printed circuit heat exchanger?

Shell and tube heat exchanger are a popular heat transfer device today. It is a tool that is widely common in various engineering systems. By transferring heat through the pipe wall, the two fluids do not mix and during the flow rate-oriented process.

The mass of each fluid is constant, i.e. heat transfer from hot water to cold water and in the oil industry Heat exchangers are common for heat transfer from higher temperature oil to lower temperature water, for example. It is called the Tube side and the fluid inside the Shell is called Shell side.

Shell and tube heat exchanger, how does it work?

Shell and tube world leader printed circuit heat exchanger working principle one fluid is in the tube and another fluid is. It will be in the shell (Shell) with baffles (Baffles) acting to control the flow direction. The fluid in the shell (Shell), which makes the flow to flow perpendicular to each other and opposite each other? It is parallel in some places

Key components in a Shell and tube heat exchanger

A tube (Shell) is the outer shell that encapsulates the entire heat exchanger, and is the part where a fluid flows through the Shell.

Tube is the part of a type of fluid that runs in the tube. This consists of a number of strands in the Shell and world leader printed circuit heat exchanger, which are called Tube Bundle.

A flange (Tube sheet) is the part that holds the tube bundle. This flange is in contact with the fluid on the shell side and the other on the other.

- Cover

- Connection tube side

- Connection shell side

Bafflers are an important component because bafflers prevent the flow in the shell from shorting, i.e. allow the fluid in the shell to fully transfer heat to the fluid in the tube.

Plate Heat Exchanger Advantages

- The total heat transfer coefficient is high. Because the fluid is designed to have counter flow characteristics.

- The amount of heat transfer can be adjusted by increasing or decreasing the number of heat transfer plates.

- Small size compared to other world leader printed circuit heat exchangerin the same amount of heat transfer. This saves installation space.

- Cheap price compared to other heat exchangers. in the same amount of heat transfer

Disadvantages Plate Heat Exchanger

- Fluid must be highly clean; otherwise the plate heat exchanger will clump and eventually break.

- The cost of a system with a plate heat exchanger is higher due to the need for a good filter system.

What is the difference between Plate Heat Exchanger and tube heat exchanger?

The differences between Plate Heat Exchanger and Shell and tube heat exchanger are as follows:

The installation area of world leader printed circuit heat exchanger is smaller than Shell and tube heat exchanger with the same amount of heat transfer. This saves installation space and can be installed vertically. The shell and tube heat exchanger requires installation length both for the piece and for maintenance when cleaning

In terms of product price, plate heat exchanger size is smaller making it cheaper. Most of the pretzels are made of stainless steel; they are widely common in the food industry. Makes it cheaper compared to Shell and tube that is all stainless steel.