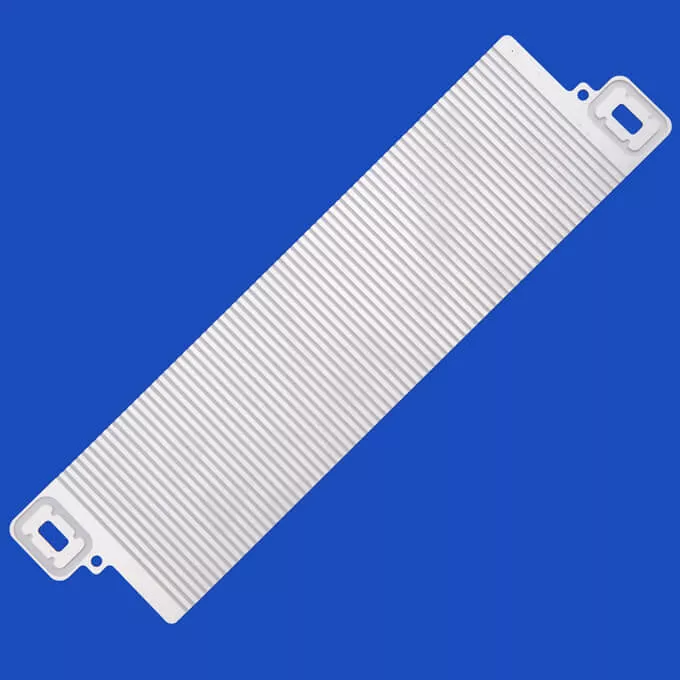

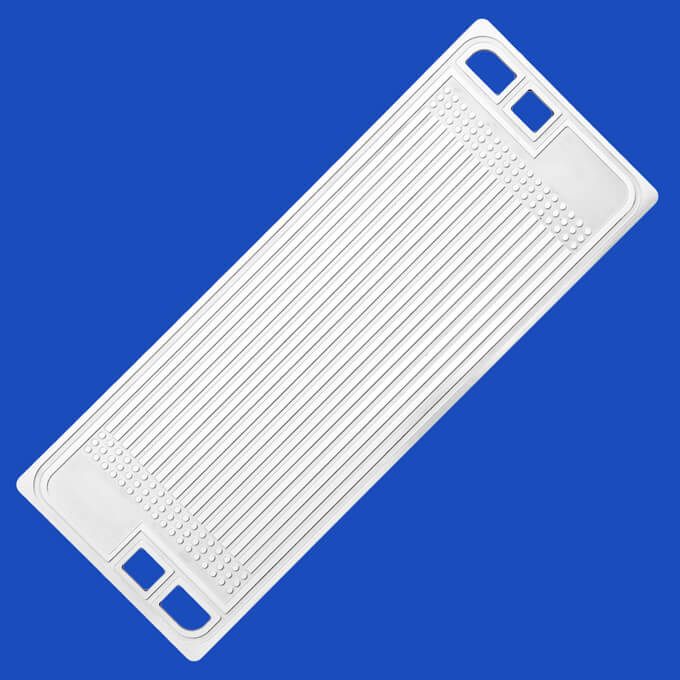

The zigzag micro channel porous flow plate is alternately filled with either the cold or the warm current. The result is that one plate is always cold and the next warm again and so on. The channel plates sit very close together.

As a result, each high-temperature plate heats the adjacent low-temperature plate. Or the other way around: every cold plate cools down the warm one. The energy is therefore transferred from the warmer to the colder medium.

What else can a plate porous flow plate do?

The main task is heat exchange. But that is not the only function of this zigzag micro channel porous flow plate. Moreover, the two streams are strictly separated from each other, which means they do not mix. This is important for a solar heating system, for example.

The energy of the solar fluid is easy to transfer to the heating water without the antifreeze it contains getting into the heating circuit.

How is a plate porous flow plate connected?

A plate porous flow plate must be installed in a vertical position. You can recognize this by the arrowhead, which must point upwards. Failure to follow these instructions will result in performance losses. Each zigzag micro channel porous flow plate has specific mounting features, for example:

- Supportive foot

- Hugging Tin Clamp

- Screwed cross bar

- Mounting studs on both cover plates

Support legs on the rear cover plate

Once the device is fixed, it is connected to the pipe network. Each device has 4 connectors on its front panel, two inputs and two outputs. Since a plate porous flow plate can process liquid and gaseous media and the streams can pass through the device in different flow directions, each model must be equipped with different connections.

Moreover, it may sound complicated, but don't worry. Each piece of zigzag micro channel porous flow plate clearly shows which is the inlet and outlet for which medium. Nevertheless, you should look very carefully to avoid mistakes. Ideally, leave this installation to a professional.

ATTENTION!

In general, a porous flow plate should only connect to pipes that come in such a way that no vibrations, impacts or jerky movements reach the porous flow plate.

Porous flow plates divide into three classes:

Direct Heat Transfer – Separable mass flows maintain using combined mass and heat transfer as in a wet cooling tower.

Indirect heat transfer - material flows are characterized by a heat-permeable wall, as is the case with a radiator. This class is also called recuperates.

- Plate porous flow plate

- Spiral porous flow plate

- Tube porous flow plate or tube bundle porous flow plate

- U-tube porous flow plate

- Heat pipes

- Jacketed tube porous flow plate

- Heating register or cooling register

- Countercurrent layer porous flow plate

Semi-indirect heat transfer – both substances come into contact with the heat accumulator with a time delay. Alternately, the hotter medium heats the storage tank while the cold medium is able to absorb the energy. One of these regenerators is the heat wheel.

- Rotary zigzag micro channel porous flow plate(air preheater)

- Schirling engine

Heat transfer: different structural framework conditions

The degree of heat transfer depends on the management of both substances. Here, too, there are five forms for different structural framework conditions:

- Countercurrent: Both substances flow past each other in the opposite direction. Ideally, the temperatures of the streams should be swapped. This is difficult to do in practice. The heat recovery of the heating system is a frequent application area.

- Direct current: Both substances flow side by side in the same direction, so that both temperatures are equalized. Reliable cooling is the big advantage here, while the material stress is higher due to the differences in temperatures.

- Cross-flow: Crossing directions of the mass flows allow acceptable counter-current and co-current heat exchange results. This zigzag micro channel porous flow plateis common to lead one of the materials flows to a specified temperature.

- Eddy current: A turbulence between two material streams of different temperatures often works wonders in terms of temperature equalization. Moreover, this can only be done with the help of a means of separating the two substances - such as a vortex tube for separating cold and hot gases.

- Cross-counterflow: The partially parallel and transverse character of the heat exchange favors an optimal exchange of the two outlet temperatures. These models are generally simpler, more streamlined and more compact.

Zigzag micro channel porous flow plate is made of metal in terms of longevity

The following materials for porous flow plates are available on the sales market:

- Metals

- Enamel

- Plastic

- Glass

- Silicon carbide

Enamel is often common for industrial applications such as chemical plants. The demands in terms of resilience, robustness and resistance to various influences - mechanical, chemical and thermal - are also often justified in industrial facilities by means of specimens made of steel.

Furthermore, aluminum and copper zigzag micro channel porous flow plate prevailed for the air conditioning area due to hygienic standards and lightweight construction. On the other hand, the aggressiveness of some chemical components requires the use of models made of refined plastic or glass.

In particular, porous flow plates made of silicon carbide are still effective at temperatures above 2200 degrees Celsius, while the functionality of many metals is collapsing.

What are the advantages of a porous flow plate?

When using a porous flow plate, the user can look forward to a number of advantageous aspects:

- Use of waste heat

- Minimizing the energy consumption

- Reduction in heating costs

- Serviceability

- Increased efficiency

- Free energy from the environment

- High living comfort

- Resource conservation

- Cooling of the output medium

- More cost-effectiveness in the overall process

How does the zigzag micro channel porous flow plate work?

In heating technology, temperatures are exchanged using a medium – a liquid or a gas – instead of direct contact. This works especially with radiators through a heat-permeable wall (radiator material), so that most of the temperature of the heated heating water can be released into the room air.

After delivery and the associated cooling, the medium is reheated by being returned to the boiler with a gas flame or the probes in the ground in the flow of a circuit - the procedure begins again. Thus, a simple law of entropy is common in the zigzag micro channel porous flow plate.

Nature always wants to exist in equilibrium. In the case of the heating system, this concerns the compensation of the heat gradient. The exchange can take place via the following media:

- Water

- Gases

- Oils

- Steam

- All common liquids and gases