The Printed Circuit Heat Exchangers (pche)

Nowadays the most latest electronic devices with high quality have printed circuit heat exchangers (pche). The rise in the trend for miniaturization of electronics and such devices can result in creating unnecessary thermal aggravation. The smaller the design, the more heat-up it will get.

These thermal hotspots within the device can cause damage as well as completely fail its functional attributes. Thermal management techniques in printed circuit heat exchangers (pche) can optimize the functionality as well as support the design features of the electronic.

Thus, printed circuit heat exchangers (pche) are very important in electrical devices. This is why electronic designers must come up with ways to cool the heated spots for the machine to function properly. There are some techniques that can help in resolving this problem. Some are feasible in reducing the heat creating elements and some can cool the device while it is actively performing.

Printed Circuit Heat Exchangers (PCHE) Thermal Management Techniques

The thermal management technique is not as simple as it seems. There is a major kind of analysis to detect the thermal power generation within the device. Moreover, analyzing the working of the device is a great way to understand any thermal problems that may arise in the future.

This is why designers have to come up with techniques and design features that associate with thermal accumulation. Sometimes even small changes like the position of different parts in the model can be enough to solve this problem.

Thermal modeling is also a way for the designers of the machine to judge the flow of heat and devise a solution using cooling techniques. The following are some of the famous heat reducing ways in printed circuit heat exchangers (pche) for better thermal control.

Identifying Thermal Hotspots

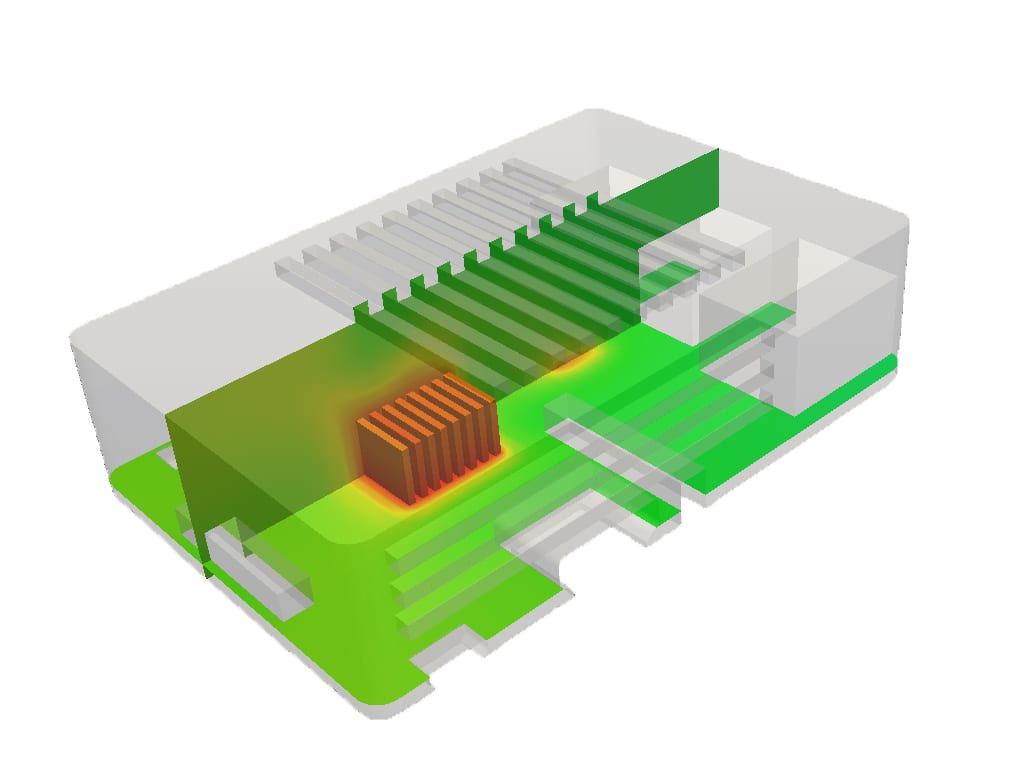

In order to avoid this problem in later stages, it is very vital to study the design of the construction of the device. The major problems can be solved in this very step if the design is carefully constructed. When talking in terms of thermal designing, it is important to recognize the major hotspot that can get heat up during the functioning of the device.

For this very reason, there are several simulation methods that can help identify the major heat-up points. Moreover, the flow of electric current analysis is also significant in this regard as it can be the very place that heats up during the functioning.

Researchers and designers have come up with a solution that geometrically places the parts of the device in such a way that they distribute evenly throughout the electronics. Another simple solution can be to places with the electric flow away from parts that are most sensitive to heat.

Thickness and Width of Copper

After keeping the design in mind and analyzing each and every placement inside the tool the next technique is the evaluating thickness and width of the copper used within. The thickness of copper must be enough to facilitate the low operative resistance of the electric route.

It is important to maintain an adequate amount of copper for the significance of the points where heat can generate especially for elevated current concentration. The appropriate amount of copper width and thickness can ensure heat reduction considerably.

Design of Pad Thickness for Thermal Management

Including other factors, the thickness of the pad is also vital when designing the printed circuit board. Usually, heat dissipates and heads for the copper layer. Hence, the pad thickness allows the heat to spread throughout rather than focusing on one or two single points.

The pad thickness guarantees that there are sinks inside the printed control board that are enough to cover heat transfer. By using the soldering technique the printed circuit boards can easily support padding thickness that helps in resulting low level of thermally resistant conditions.

Placement of High Power Components

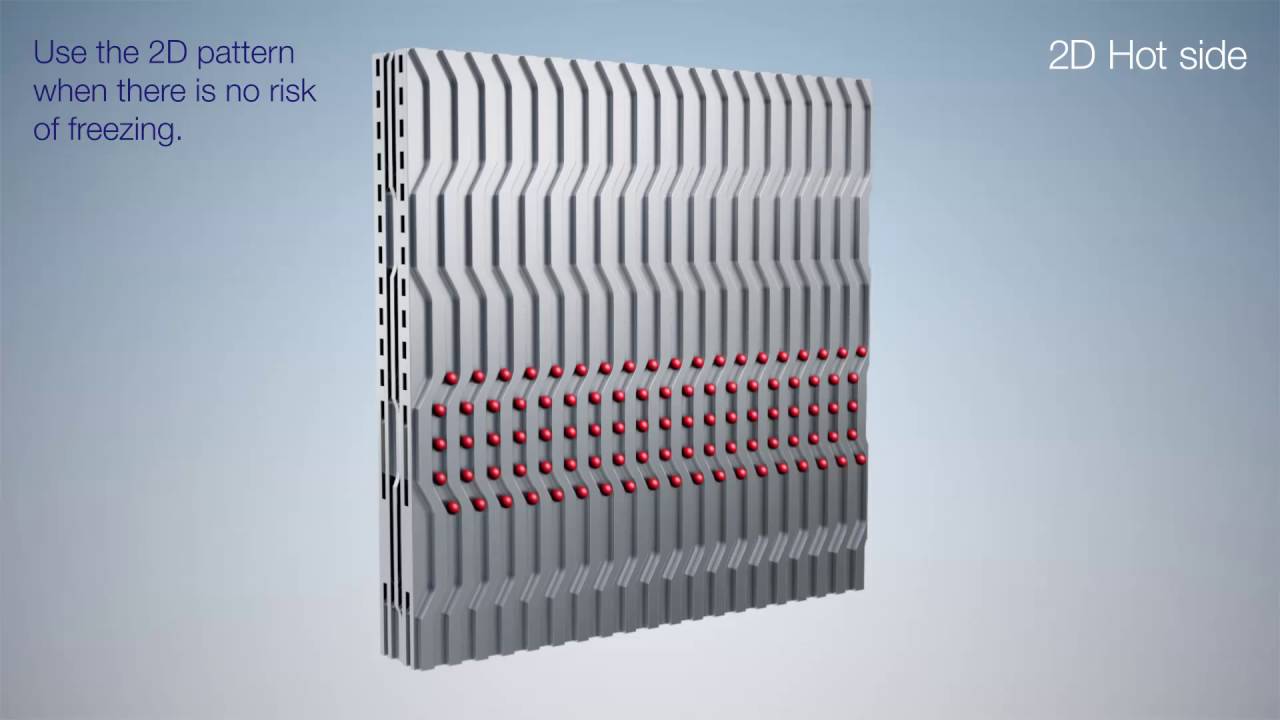

For the heat to disperse evenly throughout the printed circuit board another important factor is to place high power components strategically.

Some of these high-powered parts include central processing units and micro-controlled ones in the center of the device. If these parts have a placement near the edges of the device they can put a lot of heat concentration in that area and eventually damage it. Hence, the placement of the parts in the center can distribute the heat throughout the surfaces which can lower the stress on any one certain point.

Moreover, the placement of most sensitive devices at safe distance is also a great trick in controlling thermally generated heat.

Integration of Heat pipe

This is a very small trick yet quite effective in providing a cooling effect to the entire device. The idea is to integrate heat pipes, especially in high-temperature ranges. These high-temperature range applications include the launching of rockets and avionics. It plays a vital role as it is in a tubular shape. Heat pipes convenience the entire heat flow and its dissipation.

Furthermore, the heating pipes facilitate the transition of heat into a liquid form which further turns into vapors. This condensing can flow away from the heat accumulation in the form of vapors. These heat pipes are easy to install especially in hard-to-reach places. This allows it to capture heat generation and turn it into a vaporized form. Stollpche is an expert in providing such solutions that are trustworthy in thermal management techniques.

Summary

There can be a major setback if not for printed circuit heat exchangers (pche). When the devices are in functioning mode, they can generate a lot of thermal power. This can affect the device by damaging major components. The designers of electronics have come up with a fool-proof plan that includes some major thermal controlling techniques. Some of them include identifying the thermal hotspots, thickness, and width of the copper layer, designing the pad thickness for thermal management, placement of high power components, and integration of heat pipe. These are some methods that can prevent electronics from getting damaged in the long run.