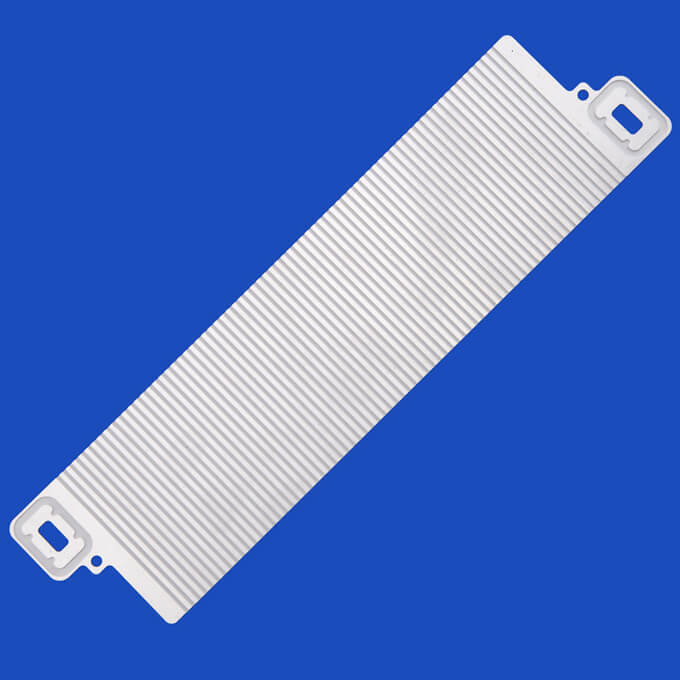

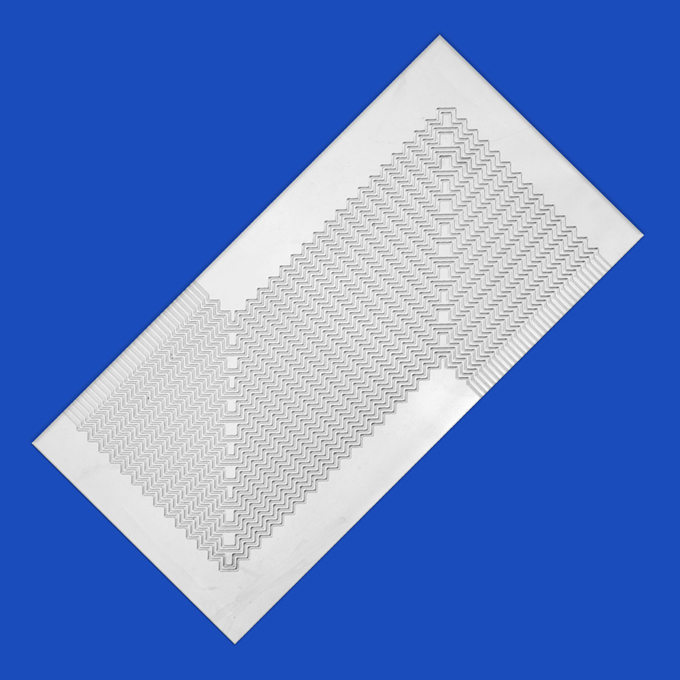

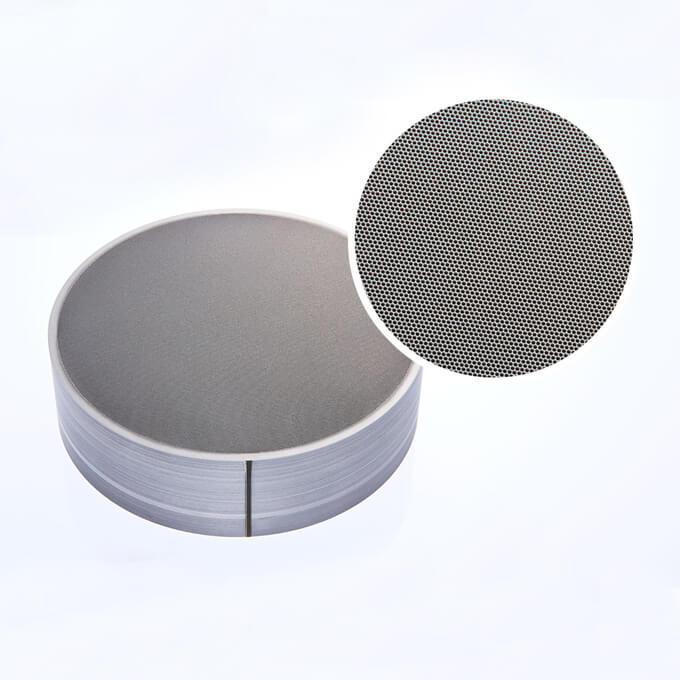

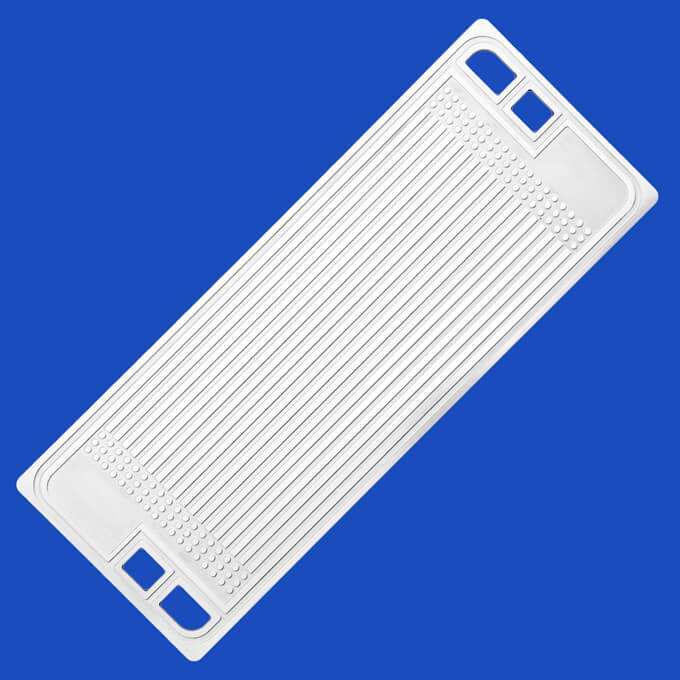

The bipolar plate is an important performance element in the fuel cell stack. It is responsible for distributing hydrogen and air to the two electrode surfaces and taking the heat generated by the reaction out of the stack. The bipolar plate has gradually developed from graphite bipolar plate to metal bipolar plate, which has become a new trend of fuel cell technology development.

A bipolar plate also called a current collecting plate, is one of the important components of the fuel cell. The utility model has the following functions and properties: separating the fuel from oxidant, preventing gas from passing through; collecting, conducting current, high conductivity; designing and processing flow channels, which can evenly distribute gas to the reaction layer of the electrode for electrode reaction; discharging heat; maintaining uniform temperature field of the battery; corrosion resistance; shock resistance and vibration resistance; thin thickness; lightweight; low cost, easy machining, suitable for batch manufacturing, etc.

Characteristics of Metal Bipolar Plate Etching in Fuel Cell

(1) The runner plate low opening dies fee, according to the design requirements of the designer to make arbitrary changes, low cost, the template production cycle is short.

(2) The new product etching design and development of runner plate is a flexible and low cost, which can realize the semi-etching of the metal surface, increase the company LOGO, realize brand, and prevent embezzlement.

(3) High precision, meets the assembly requirements of different runner plate products, the thinner the material, the higher the accuracy control. We can process 0.02 mm thick metal materials until 2 mm thick, can achieve batch production and processing, and the quality of processing is stable, batch clear, strict quality control system.

(4) Complex shape runner plate products can also be etched without additional cost. Miniaturization and diversification can also be dealt with. Opportunities to achieve customized services for different customers at home and abroad. and will not just do mass products. We have a special sample engineering team, can achieve rapid delivery of small-batch products, and quality can be guaranteed.

(5) The runner plate has no burr, pressure point, the product does not deform, does not change the material properties, does not affect the function of the product. Especially for the products with surface assembly requirements and finish requirements, the Xinhaisen etching process solves all kinds of shortcomings of stamping and wire cutting and laser cutting. At the same time, the precision can meet the requirements of the product, even better than the above processes, has irreplaceable.

(6) The thick and thin material runner plate can be processed the same to meet the requirements of different assembly components. Of course, this case is also relative, this etching process for thick and thin materials is allowed to add within the range.

(7) Almost all metal runner plates can be etched, and there is no limit to the design of various patterns. For particularly fine patterns, the etching process can also provide a good solution. Different metal materials need to be equipped with different chemical formulations. For example, rare metals: molybdenum and so on, can also be etched processing. The limit of the pattern can be wider than stamping, the ability of deep processing is strong, with precision instruments, automobile engine filter, electrical appliances, camera parts, etc., very suitable for processing.

(8) Manufacture of metal parts that can not be finished by machining. Stamping, a laser can not complete fine, ultra-thin material processing, etching easier to deal with.

| Item Name | Fuel Cell Metal Bipolar Plates |

| ODM&OEM | Yes |

| MOQ | 1 Pc |

| Supply ability | 10000 Piece/Pieces per Month |

| Port | Shenzhen |

| Delivery time | 5-10 working days |

| Payment terms | L/C,D/A,D/P,T/T |