"13th Five-Year Plan "will be the key period of solar energy industry development, its contribution to national GDP will exceed trillion yuan. The application prospect of printed circuit heat exchanger in solar thermal power collector, power generation device and the thermal storage device is great. In the future, the use of a printed circuit heat exchanger instead of the traditional heat exchanger is helpful to improve heat energy utilization, save energy and reduce production cost. At present, Stoll has developed a prototype of the solar thermal heat exchanger with a domestic enterprise.

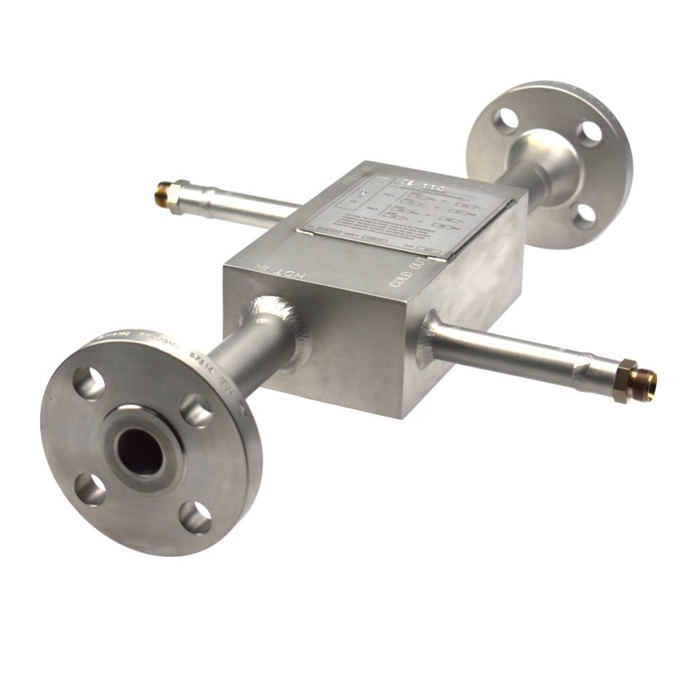

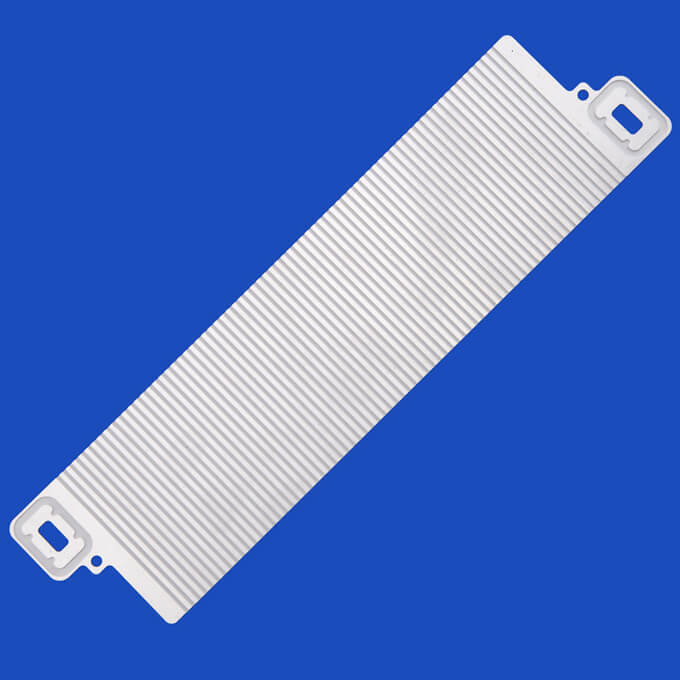

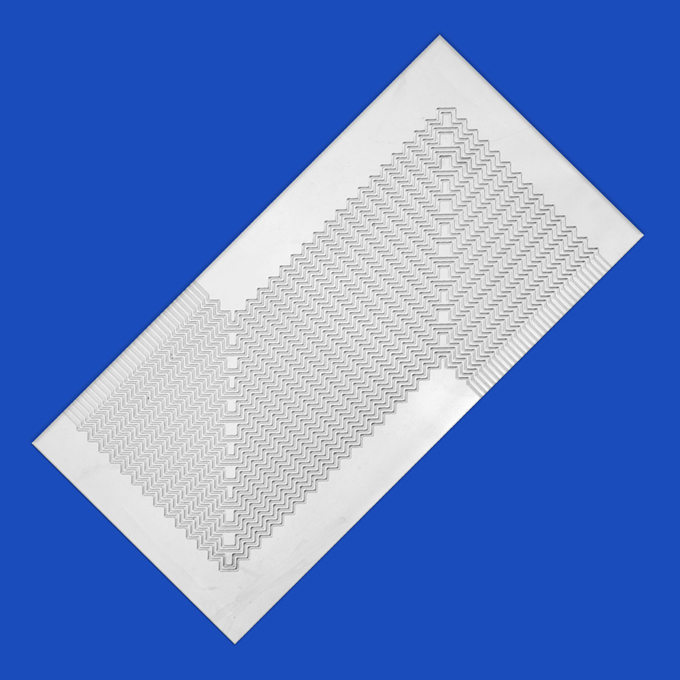

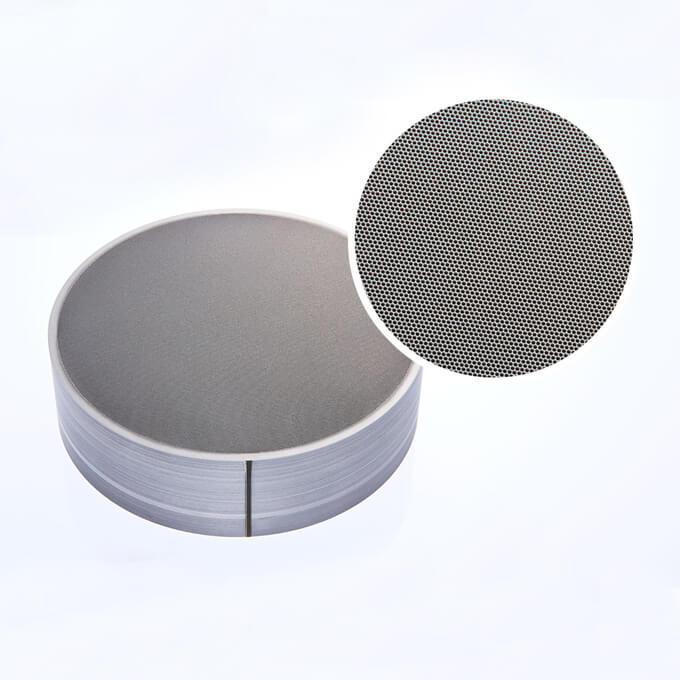

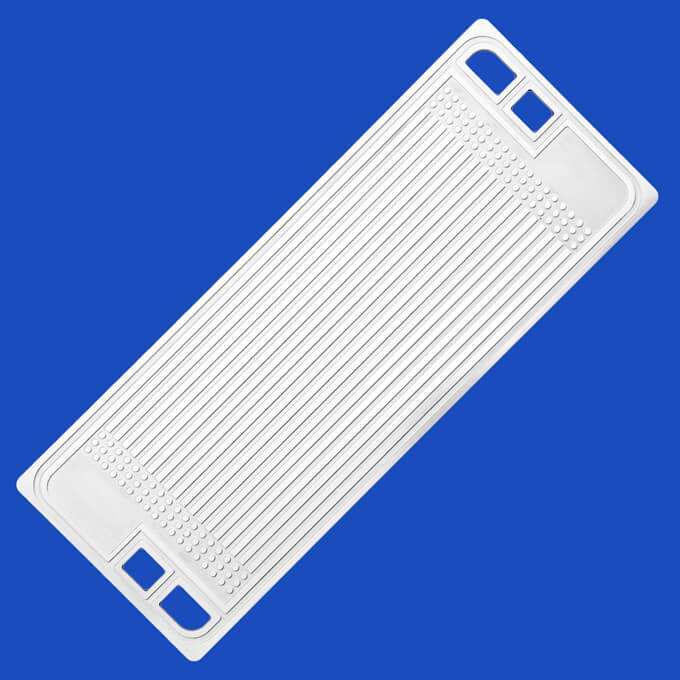

The printed circuit heat exchanger is a fine channel compact plate heat exchanger with many advantages, such as high-temperature resistance (50 MPa), high-pressure resistance (700℃), ultra-high efficiency (up to 98%), low-pressure drop, high tightness (1/6/4 of traditional tube-shell heat exchanger), corrosion resistance and long life.

The main industrial applications of printed circuit board heat exchangers are:

(1) hydrocarbon gas and gas condensate processing

Gas compression cooling, liquid resuscitation, dehydration; liquefied natural gas and other cryogenic applications; synthetic fuel production (methanol, etc.); gas separation.

(2) Fine chemicals

Reactor inlet/outlet heat exchanger.

(3) Chemical processing

Acids (nitric acid, phosphoric acid, etc.); Bases (sodium hydroxide, potassium hydroxide, etc.); Fertilizers (ammonia, urea, etc.); Petrochemicals; Pharmaceuticals; Plastics (formaldehyde, phenol, etc.); Microscopy; chemical reactors.

(4) Electricity and energy

Geothermal power generation; nuclear power; fuel cells; gas heating (gas turbines, etc).

(5) refrigeration

Cooler and condenser; cascade condenser; absorption cycle.

| Item name | Printed circuit heat exchangers for solar thermal power |

| ODM&OEM | Yes |

| MOQ | 1 pc |

| Supply ability | 10000 piece/pieces per month |

| Port | Shenzhen |

| Delivery time | 5-10 working days |

| Payment terms | L/C, D/A, D/P, T/T |