A titanium micro channel porous plate is a system in which heat is transferred from a "hot" fluid to a "cold" fluid. The goal is to save as much energy as possible from the exhaust gases.

Moreover, heat exchangers are very common devices that can also be found at home in refrigerators, stoves and air conditioners!

Something more to know about heat exchangers:

In this article you will find:

- What is a heat exchanger?

- What is a heat exchanger used for?

- The types of heat exchangers:

- Shell and tube heat exchanger:

- Plate / fin heat exchangers:

- The differences between shell and tube heat exchanger and plate heat exchanger.

What is a titanium micro channel porous plate?

The traditional boiler or central heating in your home works by burning gas and heating the water flowing in a network of pipes. Moreover, the gas burns as the water through the pipes absorbs heat energy and heats up.

However, heat exchangers are devices that allow a fluid to pass heat to a second fluid without mixing them or making them come into contact. The essential principle of a heat exchanger is to transfer heat without transferring the heat-carrying fluid.

What is a heat exchanger used for?

The purpose of titanium micro channel porous plate is to heat or cool buildings, make the motors of machines work efficiently, ensure the operation of large plants.

Moreover, in power plants or engines, the exhaust gases often contain heat that goes unnecessarily towards the outside. This is a useless waste of energy that can be easily reduced. However, the heat exchanger, placing it in the exhaust pipes and chimneys.

They are also useful for heating the office or for cooling the diesel engine of buses with the recovery of the external air which is pumped cold inside.

The types of titanium micro channel porous plate

Heat exchangers work by transferring thermal energy between two fluids at different temperatures. Moreover, they can of different types and classify on the basis of compactness. However, thermal profile, type of process and methods of contact between the currents.

The most used mode of contact between the currents is that on the surface. In which the fluids absorb heat through the surface from which they separate.

The two most common types belong to this type: the shell and tube heat exchanger and the plate heat exchanger.

Shell and tube heat exchanger:

In this type of titanium micro channel porous plate, a fluid flows through the metal pipes. The second fluid passes through a sealed envelope that surrounds them.

One fluid passes through a bundle of tubes while the other passes through the free volume between the tubes and the mantle. However, special vertical baffles, also called diaphragms, force the fluid flowing inside the mantle to assume a sinuous motion. It enhances the connective heat exchange:

Moreover, the two fluids can go: in the same direction, in opposite directions or at right angles. An example is the boilers in locomotives.

Plate / fin heat exchangers:

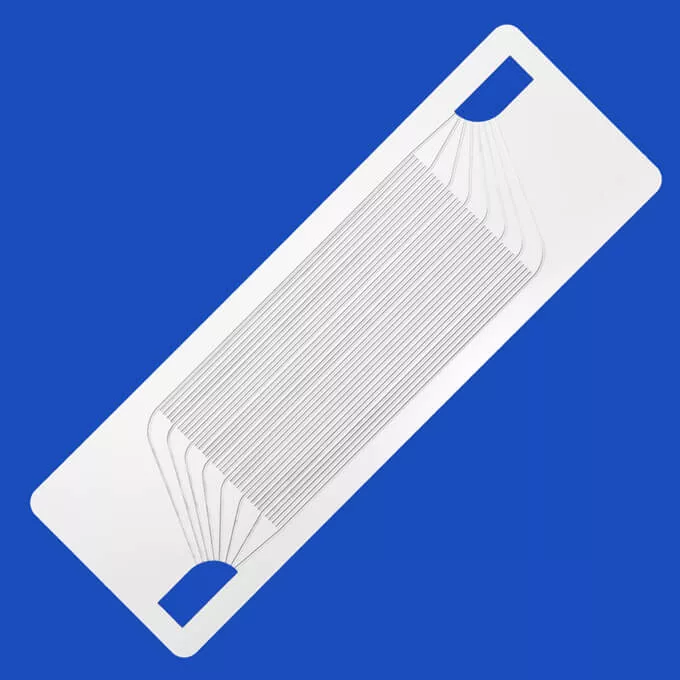

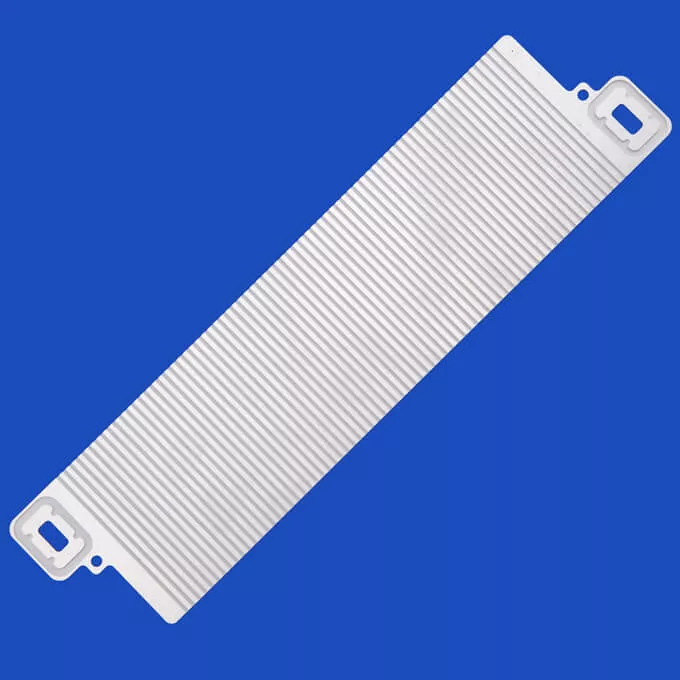

These exchangers are formed from thin metal plates or fins with a large surface area. It allows them to exchange heat as quickly as possible. However, the titanium micro channel porous plate equips with holes for the passage of the two fluids between which the heat transfer takes place.

Moreover, each plate of the exchanger is in contact on one side with the hot fluid and on the other side with the cold fluid, alternately. A gasket guarantees the seal of the channels between the plates and allows to distribute the fluids inside the channels between the plates, alternatively:

An example is gas boilers.

The differences between shell and tube heat exchanger and plate heat exchanger.

"So what is the most suitable exchanger for my needs?"

The answer is: it depends!

Coefficient and the flexibility of the plate heat exchanger

For example, the main strengths of the titanium micro channel porous plate are the small footprint, the high heat exchange coefficient and the flexibility, given by the possibility of easily adding new plates.

On the other hand, the presence of gaskets usually limits the field of use to pressures below 25 bar and at temperatures below 250 ° C. However, there is also a technical limit on the dimensions that can reach by the plates.

Components of the Tube Bundle Heat Exchanger

U-shaped tube bundle heat exchanger components

Junction element, consisting of a circular crown fixed to the end of the element and provide with a series of equidistant holes for inserting the tightening bolts.

- Flat flange

Moreover, element inserted between two metal surfaces of titanium micro channel porous plate, in order to ensure sealing with respect to a fluid.

- Diathermic Oil:

- Steam

- Superheated water

- Hot water

Group of tubes traversed by the fluid.

- Copper Cu

- Special execution: titanium

The end plates of the appliances themselves to which the pipes attach.

- Quality carbon steel

- Special executions

Element that serves to divide into parts.

- Quality carbon steel

- Special execution

Main structure of the heat exchanger

- Quality carbon steel, and external painted head with anti-rust

- Special executions: AISI 304/316 stainless steel

Heat Exchanger Nameplate

However, each heat exchanger equips with a “data plate” containing the relative characteristics. Moreover, it is important to keep it for future traceability of the appliance.

Finally, the high turbulence causes a high rate of erosion of the surfaces of the plate exchanger.

The shell and titanium micro channel porous plate have important dimensions

However, it is very robust and its shape makes it suitable for applications under pressure. Thanks to their versatility of use and ease of maintenance, they are still the most used in civil and industrial systems.

In particular, they design for large thermal power stations, hospitals, airports, sports facilities and communities. Moreover, at the forefront from a technological and energy saving point of view, they confirm the know-how and international prestige of a company that has been known and appreciated over time.