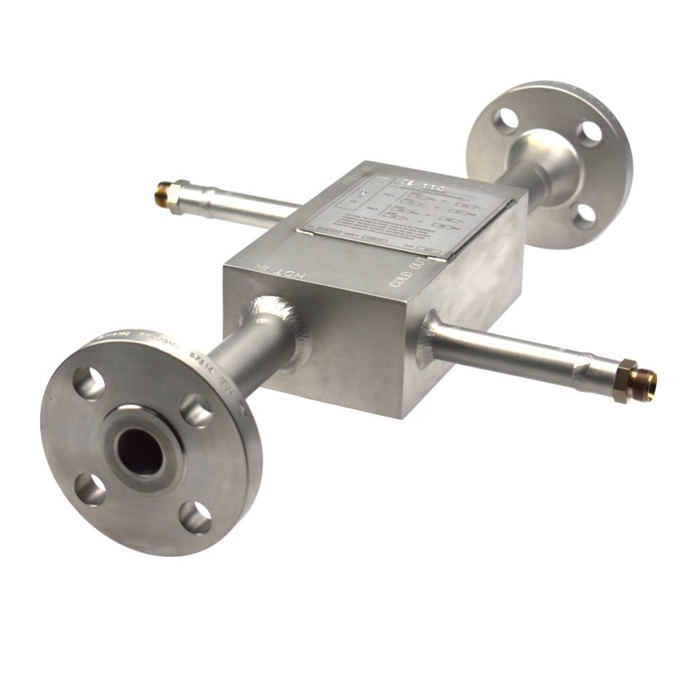

In recent years, with the shortage of resources and environmental pollution, the adjustment of industrial structure and the realization of energy-saving and emission reduction of heat exchangers have gradually become the focus of the development of the petrochemical industry. A few days ago, Stoll was commissioned by a petrochemical research institute to develop the first printed circuit heat exchanger prototype for the petrochemical industry in China. The heat exchanger has the advantages of high-temperature resistance, high-pressure resistance, small volume, lightweight and high heat transfer coefficient, which makes it possible to replace the traditional heat exchanger in the production process of mechanical lubricating oil and fresh water and related intermediate products in the petrochemical field.

The printed circuit heat exchanger is a fine channel compact plate heat exchanger with many advantages, such as high temperature resistance (50 MPa), high-pressure resistance (700℃), ultra-high efficiency (up to 98%), low-pressure drop, high tightness (1/6/4 of traditional tube-shell heat exchanger), corrosion resistance and long life.

The main industrial applications of printed circuit board heat exchangers are:

(1) hydrocarbon gas and gas condensate processing

Gas compression cooling, liquid resuscitation, dehydration; liquefied natural gas and other cryogenic applications; synthetic fuel production (methanol, etc.); gas separation.

(2) Fine chemicals

Reactor inlet/outlet heat exchanger.

(3) Chemical processing

Acids (nitric acid, phosphoric acid, etc.); Bases (sodium hydroxide, potassium hydroxide, etc.); Fertilizers (ammonia, urea, etc.); Petrochemicals; Pharmaceuticals; Plastics (formaldehyde, phenol, etc.); Microscopy; chemical reactors.

(4) Electricity and energy

Geothermal power generation; nuclear power; fuel cells; gas heating (gas turbines, etc).

(5) refrigeration

Cooler and condenser; cascade condenser; absorption cycle.

| Item Name | Petrochemical Printed Circuit Heat Exchanger |

| ODM&OEM | Yes |

| MOQ | 1 Pc |

| Port | Shenzhen |

| Delivery time | 5-10 working days |

| Payment Terms | L/C, D/A, D/P, T/T |